Table of Contents

BMW F30 Electric Water Pump Failure Causes Overheating and Head Gasket Damage

The BMW F30 platform has gained notoriety amongst owners for a particularly troublesome issue: premature electric water pump failures that can lead to catastrophic engine damage. This problem affects multiple engine variants including the N20, N26, and N55 units, and has become one of the most documented reliability concerns for these vehicles.

Understanding the warning signs and taking preventive action can save BMW F30 owners thousands of pounds in repair costs whilst avoiding the inconvenience of sudden breakdowns.

Table: Issues

| Issue | Cause | Symptoms | Preventive Tip |

|---|---|---|---|

| Water Pump Failure | Heat cycles, electric motor wear, coolant contamination | Overheating warnings, blown fuse F87, sudden coolant loss | Replace pump every 70,000 km / 43,000 mi |

| Head Gasket Damage | Prolonged engine overheating | White exhaust smoke, milky oil, coolant loss | Stop driving immediately if temp warning appears |

| Electrical Cooling Faults | Corroded wires, bad grounds, failed pump motor | Intermittent cooling, warning lights, fuse blowouts | Check fuses and grounds before replacing pump |

| Plastic Flange & Housing Cracks | Age-related plastic fatigue | Coolant leaks, air in system, overheating | Upgrade to aluminium fittings where possible |

| Thermostat Failure | Stuck closed, age-related failure | Overheating without warning, poor heater performance | Replace with pump to save on labour |

What Makes the BMW F30 Electric Water Pump Fail Early

The electric water pump in BMW F30 models typically fails well before reaching acceptable service intervals. Many owners report failures occurring between 50,000 and 65,000 miles, significantly shorter than the expected lifespan of such components.

Several factors contribute to these premature failures. Heat cycling places enormous stress on the pump's internal components, particularly the electric motor and plastic housing. The constant expansion and contraction weakens seals and electrical connections over time.

Coolant contamination presents another significant risk factor. When coolant becomes acidic or contaminated with debris, it accelerates wear on the pump's impeller and internal passages. This contamination often stems from degraded plastic cooling system components elsewhere in the system.

RIDEX Water pump

Cast Aluminium, with belt pulley, with gasket/seal, Mechanical, Plastic

RIDEX Water pump

Cast Aluminium, with belt pulley, with gasket/seal, Mechanical, Plastic

RIDEX Water pump

RIDEX Water pump

FEBI BILSTEIN Water pump

Cast Aluminium, with seal ring, Plastic

FEBI BILSTEIN Water pump

Cast Aluminium, with seal ring, Plastic

Common Warning Signs of Water Pump Failure

BMW F30 owners should watch for several telltale symptoms that indicate impending water pump failure. The most obvious warning comes through the vehicle's temperature monitoring system, which may display orange or red overheating alerts on the dashboard.

These warnings often appear suddenly, sometimes immediately after routine maintenance work such as thermostat replacement. The abrupt nature of these failures frequently catches drivers off guard, as the pump may function normally one day and fail completely the next.

Electrical symptoms can also indicate water pump problems. A blown fuse in the cooling system circuit, particularly fuse F87, often points to pump motor failure. Similarly, faulty earth connections can cause intermittent pump operation, leading to inconsistent cooling performance.

The notorious "Mickey Mouse flange" and other plastic cooling system components frequently develop cracks that compound water pump issues. When these plastic parts fail, they can introduce air into the system or cause coolant loss, forcing the pump to work harder and accelerating its demise.

Engine Overheating Consequences and Head Gasket Risks

When the electric water pump fails, engine overheating becomes inevitable. Modern BMW engines operate at precisely controlled temperatures, and even brief overheating episodes can cause permanent damage.

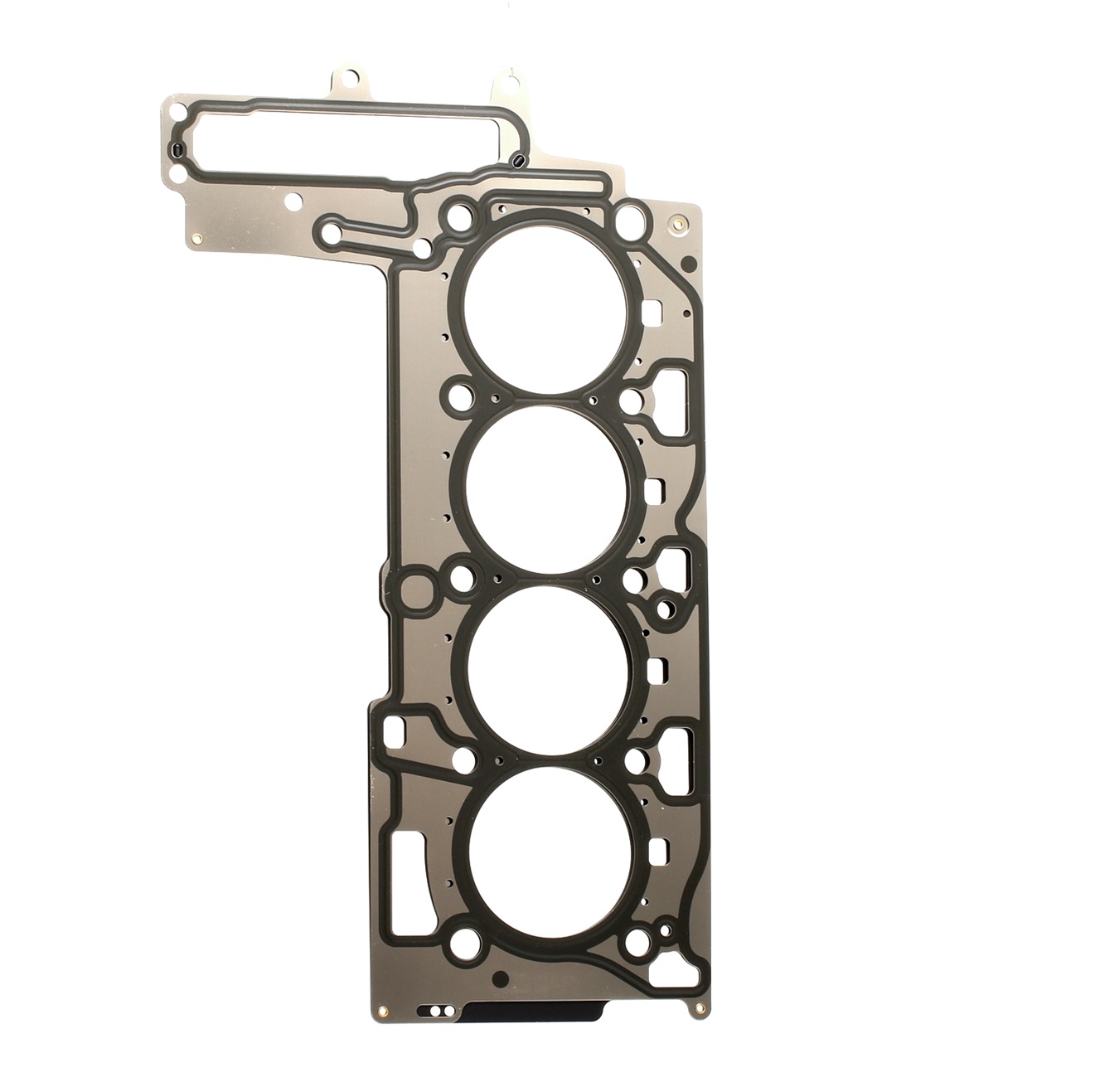

The cylinder head gasket faces particular vulnerability during overheating events. As temperatures rise beyond normal operating ranges, the cylinder head expands at a different rate than the engine block. This differential expansion can compromise the head gasket seal, allowing coolant and oil to mix.

Signs of head gasket failure include milky oil on the dipstick, unexplained coolant loss, and white smoke from the exhaust. However, drivers should exercise caution when interpreting these symptoms, as condensation under the oil filler cap during winter months can appear similar to coolant contamination.

Continued driving with an overheating engine almost guarantees expensive repairs. The cylinder head itself may warp beyond repair limits, necessitating replacement or professional machining services.

Diagnostic Procedures for Water Pump Problems

Proper diagnosis requires a systematic approach to identify the root cause of cooling system problems. Begin by checking all relevant fuses, particularly those controlling the cooling fans and water pump motor.

Visual inspection of the pump and surrounding components often reveals obvious problems. Look for coolant leaks around the pump housing, corroded electrical connections, or damaged wiring harnesses.

A cooling system pressure test provides definitive evidence of leaks throughout the system. This test can identify failing components before they cause complete system breakdown, including the expansion tank, radiator, and various hoses.

Testing the pump's electrical supply and earth connections helps distinguish between mechanical pump failure and electrical faults. Many apparent pump failures actually stem from simple wiring problems that cost far less to repair than pump replacement.

Replacement Strategy and Component Selection

When replacing a failed water pump, the experts from Autodoc recommend changing the water pump every 70,000 km (~43,000 miles) as a preventive measure. This proactive approach helps avoid unexpected failures and the associated risks of engine damage.

Quality of replacement parts significantly impacts long-term reliability. Original Equipment Manufacturer (OEM) parts or equivalent quality alternatives provide the best durability, though they command higher prices than budget alternatives.

Consider upgrading vulnerable plastic components to aluminium alternatives where available. These upgrades improve system reliability and reduce the likelihood of cascading failures affecting the new water pump.

Replacing the thermostat simultaneously with the water pump often proves worthwhile, as both components work closely together and share similar service intervals. This approach minimises labour costs and reduces the risk of subsequent cooling system problems.

PIERBURG Water pump

Electric, Plastic

PIERBURG Water pump

Electric, Plastic

VALEO Water pump

without belt pulley, with gaskets/seals, without lid

VALEO Water pump

without belt pulley, with gaskets/seals, without lid

Prevention and Maintenance Recommendations

Regular cooling system maintenance dramatically reduces the risk of premature water pump failure. Ensure coolant changes occur according to BMW's service schedule, typically every four years or 60,000 miles.

Monitor coolant levels monthly and investigate any unexplained loss immediately. Small leaks often precede major component failures, providing early warning opportunities for preventive action.

Keep detailed records of any cooling system work, including pump replacements, thermostat changes, and coolant services. This documentation helps identify patterns and ensures appropriate maintenance intervals.

Consider upgrading to higher-quality coolant formulations that provide better corrosion protection and thermal stability. These premium products cost more initially but can extend component lifespan significantly.

Key Takeaways

- BMW F30 electric water pump failures typically occur between 50,000-65,000 miles

- Overheating warnings require immediate attention to prevent head gasket damage

- Electrical faults and plastic component degradation contribute to pump failures

- Pressure testing and electrical diagnostics help identify root causes

- Preventive replacement every 70,000 km reduces breakdown risks

- Quality replacement parts and simultaneous thermostat replacement improve reliability

A useful video on this topic: