Table of Contents

BMW E90 Turbo Failures and How to Prevent Them

Turbo failure affects BMW E90 diesel models more frequently than petrol variants, with maintenance quality being the primary determining factor. Poor servicing schedules and contaminated oil commonly contribute to turbocharger problems in these vehicles, making prevention crucial for long-term reliability.

Why BMW E90 Diesel Models Experience More Turbo Problems

BMW E90 diesel engines, particularly the 320d and 330d variants, operate their turbochargers under extreme conditions. The turbine reaches temperatures exceeding 900°C whilst spinning at speeds up to 200,000 RPM. These demanding operating parameters make diesel turbos more susceptible to failure when maintenance standards drop.

The main contributing factors include oil contamination from extended service intervals, carbon buildup in the intake system, and thermal stress from frequent short journeys. Unlike petrol engines, diesel turbos work harder during everyday driving, increasing wear rates when proper care isn't maintained.

Table: Most Affected BMW E90 Models

| Model | Turbo Failure Rate |

|---|---|

| 318d | Moderate |

| 320d | High |

| 325d | Moderate |

| 330d | High |

| 335d | High |

Common Causes of BMW E90 Turbo Failure

Oil Contamination and Quality Issues

Contaminated engine oil causes 60% of turbo failures in BMW E90 models. When oil change intervals exceed manufacturer recommendations, sludge accumulates within the turbo's bearing housing. This sludge restricts oil flow, causing bearing wear and eventual shaft failure.

Using incorrect oil viscosity compounds the problem. BMW E90 diesel engines require fully synthetic oil meeting BMW Longlife-04 specification. Conventional oils break down under the extreme temperatures generated by the turbocharger, creating carbon deposits that block oil passages.

Carbon Buildup in Intake System

Carbon deposits accumulate on the compressor wheel and intake valves over time. This buildup reduces airflow efficiency and can cause compressor surge, leading to bearing damage. Vehicles used primarily for short journeys experience more severe carbon accumulation because the engine doesn't reach optimal operating temperatures.

Bearing Failure from Heat Cycling

Frequent temperature cycling weakens turbo bearings. When drivers shut off the engine immediately after hard driving, residual heat causes oil coking around the bearings. This creates abrasive particles that accelerate wear during subsequent startups.

Recognising BMW E90 Turbo Failure Symptoms

Loss of Power and Performance

The most noticeable symptom is reduced engine power, particularly during acceleration. Boost pressure drops below normal levels, typically from 1.2 bar to less than 0.8 bar. This power loss becomes more pronounced under load, such as climbing hills or overtaking.

Excessive Exhaust Smoke Production

Blue smoke indicates oil consumption through worn turbo seals. The turbo burns approximately 0.5 to 0.7 litres of oil per 1,000 miles when seals fail. Black smoke suggests unburnt fuel from insufficient air delivery, whilst white smoke may indicate coolant entering the combustion chamber through a cracked turbo housing.

Graph suggestion: Exhaust Smoke Colours and Their Meanings

- Blue smoke: Oil consumption (turbo seal failure)

- Black smoke: Rich fuel mixture (air delivery issues)

- White smoke: Coolant leak (housing damage)

Unusual Noises from Engine Bay

Failing turbos produce distinctive sounds. A high-pitched whistling noise during acceleration indicates compressor wheel damage or bearing wear. Rattling sounds suggest loose components within the turbo assembly, whilst grinding noises indicate severe bearing failure requiring immediate attention.

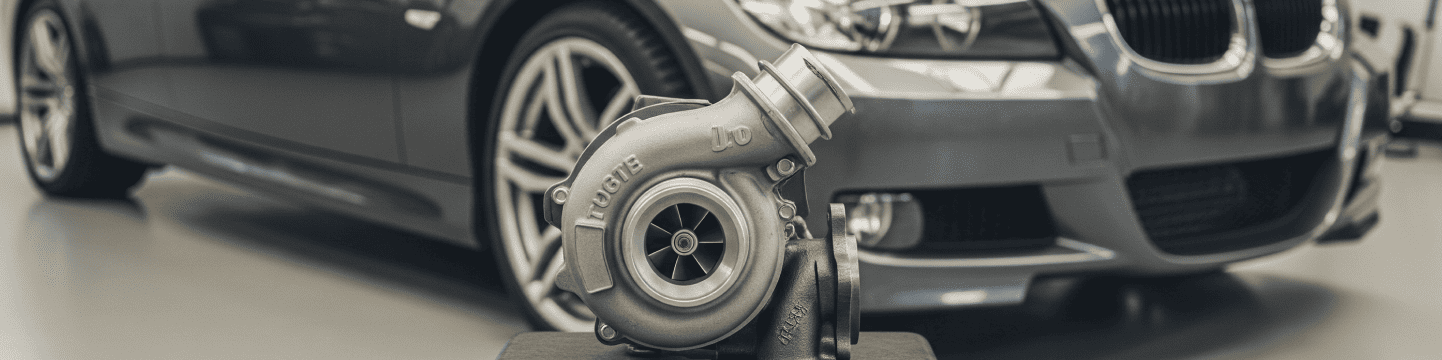

RIDEX CHRA turbo

RIDEX CHRA turbo

RIDEX Turbocharger

Exhaust Turbocharger, Diesel, Air cooled, Incl. Gasket Set, with fastening/mounting material

RIDEX Turbocharger

Exhaust Turbocharger, Diesel, Air cooled, Incl. Gasket Set, with fastening/mounting material

RIDEX Turbocharger

Exhaust Turbocharger, Electric, without fastening/mounting material

RIDEX Turbocharger

Exhaust Turbocharger, Electric, without fastening/mounting material

RIDEX Turbocharger

Exhaust Turbocharger, Electric, Incl. Gasket Set

RIDEX Turbocharger

Exhaust Turbocharger, Electric, Incl. Gasket Set

Preventing Turbo Failure in BMW E90 Models

Proper Oil Change Intervals

Change engine oil every 10,000 miles or 12 months, whichever comes first. Whilst BMW recommends longer intervals, frequent oil changes significantly extend turbo life. Use only BMW Longlife-04 approved oil with the correct viscosity rating for your specific engine.

Check oil levels weekly, as turbos can consume oil even when functioning normally. Maintain oil levels between the minimum and maximum marks on the dipstick. Low oil levels cause bearing damage within minutes of operation.

Allowing Proper Cool-Down Periods

After spirited driving or motorway journeys, idle the engine for 2-3 minutes before switching off. This allows the turbo to cool gradually and prevents oil coking. Install a turbo timer if you frequently drive in demanding conditions.

Regular Intake System Cleaning

Clean the intake system every 40,000 miles to remove carbon deposits. Use appropriate cleaning chemicals designed for diesel engines, or have the system professionally cleaned. Regular cleaning maintains optimal airflow and prevents compressor surge.

When to Replace Your BMW E90 Turbo

Replace the turbocharger when boost pressure consistently drops below 0.9 bar during testing, or when oil consumption exceeds 1 litre per 1,000 miles. Continuing to drive with a severely damaged turbo risks catastrophic engine failure through oil starvation or debris ingestion.

Professional diagnosis using VAG-COM or similar diagnostic equipment provides accurate boost pressure readings and fault codes. Common fault codes include P003A (turbocharger boost control) and P0299 (turbocharger underboost condition).

Replacement Options for BMW E90 Turbos

Original Equipment Manufacturer Parts

OEM turbos provide exact fitment and original performance characteristics. Genuine BMW parts offer the highest quality and reliability, with professional installation recommended for optimal results. These units typically last 100,000-150,000 miles with proper maintenance.

Aftermarket Alternatives

Quality aftermarket turbos offer similar performance at reduced cost compared to OEM options. The experts from Autodoc have appropriate replacement BMW E90 turbos that meet OEM specifications whilst providing better value. Aftermarket units represent significant savings over genuine parts whilst maintaining quality standards.

RIDEX REMAN Turbocharger

Exhaust Turbocharger, electronically controlled, without fastening/mounting material

RIDEX REMAN Turbocharger

Exhaust Turbocharger, electronically controlled, without fastening/mounting material

STARK Turbocharger

Exhaust Turbocharger, Oil-cooled, Electric, without an electric divert-air valve, with gaskets/seals, without exhaust manifold

STARK Turbocharger

Exhaust Turbocharger, Oil-cooled, Electric, without an electric divert-air valve, with gaskets/seals, without exhaust manifold

Remanufactured Units

Professionally remanufactured turbos provide a cost-effective solution for high-mileage vehicles. These units undergo complete rebuilding with new seals, bearings, and worn components. Quality remanufactured turbos come with appropriate warranties and offer excellent value for older vehicles.

Key Takeaways

- BMW E90 diesel models experience higher turbo failure rates than petrol variants

- Poor maintenance causes many turbocharger problems

- Oil contamination and carbon buildup are primary failure causes

- Regular oil changes every 10,000 miles significantly extend turbo life

- Proper cool-down periods prevent oil coking and bearing damage

- Professional diagnosis is essential before replacement decisions

- Aftermarket alternatives provide excellent value whilst maintaining quality

Maintaining your BMW E90's turbo requires attention to detail and adherence to proper service intervals. With correct care, these robust engines provide reliable performance for well over 200,000 miles.

A useful video on this topic: