Problems with the Audi A8

Reliability Audi A8: common problems, issues symptoms and faults

- Timing chain problems in 4.2 TDI engines: The timing chain often shows the first signs of wear after 150,000-200,000 km, which manifests itself as rattling when starting from cold. In extreme cases, the chain can cause problems after just 80,000 km, especially if maintenance is irregular.

- Air suspension defects: The adaptive air suspension system often fails after 100,000-150,000 km, where individual air bellows or the compressor may fail. Symptoms include uneven vehicle ride height and error messages in the display.

- Electronic problems in the MMI system: The multimedia interface does not function correctly, especially in models built from 2010 onwards. Frequent complaints concern frozen screens and unresponsive touch controls after 60,000-100,000 km.

- Automatic transmission faults: The Tiptronic gearbox does not shift properly, especially in 3.0 TDI and 4.0 TFSI engines. The first signs often occur between 120,000-180,000 km, with jerky gear changes as typical symptoms.

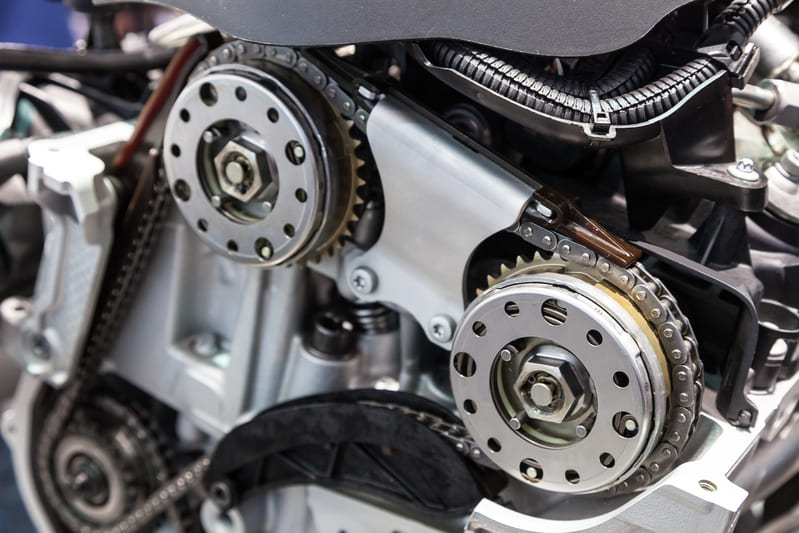

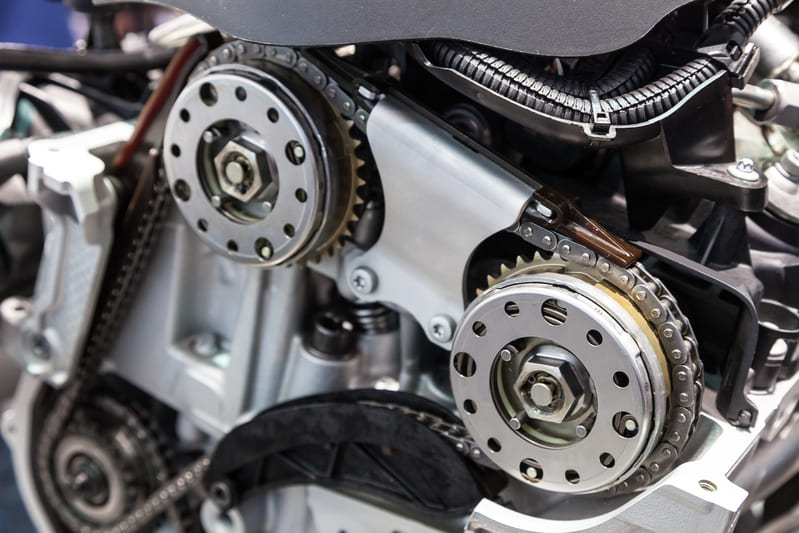

Audi A8: Problems with the timing chain in 4.2 TDI engines

The timing chain of the 4.2 TDI engine shows characteristic weak points, which are noticeable through metallic rattling when starting cold. These frequent faults occur particularly in vehicles with higher mileages, whereby the service life depends heavily on the maintenance history. The problem initially manifests itself as slight noises, which develop into distinct rattling noises as wear progresses. In extreme cases, the chain may break completely, resulting in serious engine damage. The reliability of the engine depends largely on regular oil changes and the use of high-quality engine oils.

A systematic check is essential for the early detection of timing chain problems. The precise Audi A8 timing chain tensioners require regular checks every 60,000 kilometres to ensure optimum tension. Diagnosis is made by listening to the engine at idle and at various engine speeds, and an endoscope can be used for visual inspection. At the first signs, a workshop should be visited immediately, as timely replacement prevents more costly consequential damage.

Audi A8: Problems with the air suspension

The adaptive air suspension system of the Audi A8 develops typical faults that manifest themselves in uneven vehicle ride height and loss of comfort. These faults often occur after 100,000-150,000 kilometres, with the air bellows on the rear axles being particularly susceptible. The symptoms usually begin with a slow overnight drop in one corner of the vehicle, followed by error messages in the on-board computer. The air suspension compressor then works excessively often, which leads to its premature wear. In cold temperatures, the problems are exacerbated as the rubber membranes of the air bellows become brittle and can develop cracks.

Regular maintenance is crucial for the longevity of the air suspension. The sensitive Audi A8 air suspension components require annual visual inspections for cracks and leaks, especially at the bellows. Diagnosis is carried out via the on-board diagnostics system, which displays specific fault codes for defective sensors or leaking air bellows. Preventive measures include regular cleaning of the air filters and replacement of the air dryer cartridge every 80,000 kilometres to prevent moisture in the system.

Audi A8: Problems with the MMI system and electronics

The multimedia interface (MMI) of the Audi A8 shows characteristic electronic faults, which manifest themselves in frozen screens and unresponsive operation. These complaints occur more frequently in vehicles with 60,000 kilometres or more, and temperature changes and humidity can exacerbate the problems. The system does not start or responds to inputs with a delay, which is particularly problematic for navigation and climate control. Frequent faults also affect the Bluetooth connection and the telephone system, which function intermittently or fail completely. The complex electronics are susceptible to voltage fluctuations and can be affected by defective control units.

Professional maintenance is required to diagnose and rectify MMI problems. The complex Audi A8 electronic modules require regular software updates and system checks to ensure optimum functionality. Fault diagnosis is carried out using special diagnostic devices that can read fault codes from various control units. Solutions include software updates, re-initialising the system or, in serious cases, replacing defective control units. Regular battery checks are important, as weak batteries can lead to electronic problems.

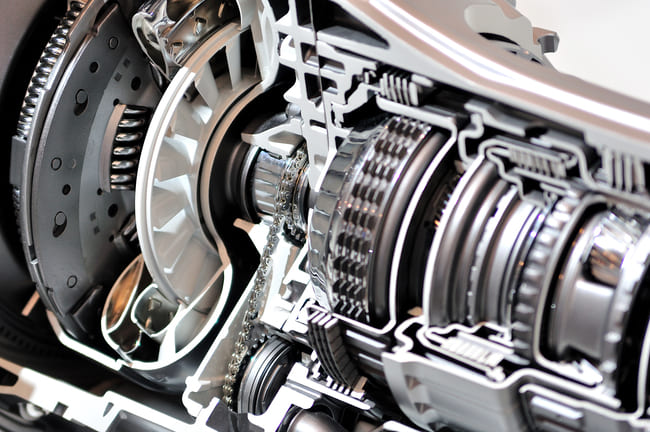

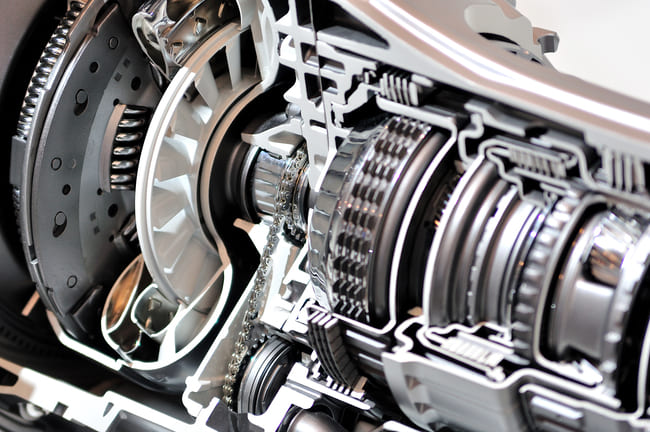

Audi A8: Problems with the automatic transmission

The Tiptronic automatic transmission of the Audi A8 develops specific weaknesses, which manifest themselves in jerky gear changes and delayed gear changes. These faults occur particularly in 3.0 TDI and 4.0 TFSI engines after 120,000-180,000 km, whereby the service life depends heavily on driving style and maintenance. The transmission does not shift properly into the desired gear or remains in one gear for too long, which leads to increased fuel consumption. In the case of advanced problems, the transmission can switch to emergency mode, which means that only a few gears are available. Common causes are worn clutches, defective valve bodies or problematic control units.

A professional inspection is essential for the correct diagnosis of transmission problems. The precise Audi A8 transmission control units require regular software updates and adjustments every 100,000 km for optimum shift quality. Diagnostics include checking the transmission fluid, pressure testing the hydraulic systems and analysing fault codes. Preventive maintenance includes regular transmission oil changes every 60,000 km and the use of original oils. If detected early, often only valve bodies or control units can be replaced, which is less expensive than a complete transmission replacement.

Audi A8: Problems with the 6.0 W12 engine

The exclusive 6.0 W12 engine of the Audi A8 exhibits specific problems that mainly affect the complex engine management and cooling system. These breakdowns manifest themselves in rough idling, loss of power and increased oil consumption, especially after 80,000-120,000 kilometres. The twelve cylinders require precise tuning, and even small irregularities in the fuel supply or ignition can lead to noticeable problems. Common complaints include defective ignition coils, clogged injectors and problems with the variable valve timing. The engine is particularly susceptible to overheating under high loads as the complex cooling system is prone to leaks.

A systematic check is crucial to maintaining W12 engine performance. The demanding Audi A8 W12 components require high-quality engine oils and shorter service intervals every 10,000 km instead of the standard 15,000 km. Diagnostics require specialised equipment to monitor all twelve cylinders individually, including compression tests and endoscopy. Preventive maintenance includes regular cooling system flushes, replacement of ignition coils every 60,000 km and the use of premium fuels to prevent deposits.

Audi A8: Problems with the 3.3 TDI engine

The 3.3 TDI engine shows characteristic weak points in the exhaust gas recirculation and turbocharger area, which are characterised by a loss of power and black smoke development. These common faults typically occur after 150,000-200,000 km, whereby short journeys can exacerbate the problems. The EGR valve cokes up due to soot deposits and does not function properly, resulting in uneven engine running and increased emissions. The variable turbocharger can lose efficiency due to wear of the guide vanes, resulting in a noticeable reduction in engine performance. In addition, the engine is prone to problems with the particulate filter, especially when used predominantly in urban areas.

Regular maintenance is essential for the reliability of the 3.3 TDI engine. The sensitive Audi A8 TDI systems require regular cleaning of the EGR valve every 80,000 km and professional particulate filter regeneration. Diagnostics include checking the exhaust gas values, pressure measurements in the intake system and checking the turbocharger geometry. Preventive measures include regular motorway driving for natural regeneration of the particulate filter and the use of high-quality diesel fuels with additives for system cleaning.

Additional common faults of the Audi A8

Based on the experiences of Audi A8 drivers, the following additional problems occur:

- Defective xenon headlights: burners often fail after 60,000-80,000 km, ballasts show problems after 100,000 km

- Problems with the parking heater: malfunctions often occur after 80,000-120,000 km, especially in diesel models due to coking

- Door lock mechanism defects: Electronic door handles often fail after 100,000-150,000 km due to microswitch wear

- Air conditioning compressor problems: Compressor failure typically after 120,000-180,000 km, especially on 3.7 V8 models

- Navi-DVD drive faults: Mechanical faults of the DVD drive after 80,000-120,000 km due to dust and wear

- Premature brake disc wear: Especially on the front axle after 40,000-60,000 km with a sporty driving style

- Battery problems: weakening of the main battery after 80,000-100,000 km, additional battery for comfort systems after 60,000 km

Audi A8: weaknesses and strengths

| Strengths |

Weak points |

| Outstanding driving comfort |

High repair costs |

| Modern assistance systems |

Complex electronics |

| Powerful engines |

Air suspension problems |

| High-quality workmanship |

Timing chain wear |

| Extensive equipment |

MMI system malfunctions |

| Prestigious design |

Transmission problems |

| Good road holding |

High maintenance requirements |

The Audi A8 represents luxury and technical sophistication, but requires consistent maintenance and expert care. Most problems can be avoided or at least their effects limited by preventive measures and timely intervention. The complex electronic systems and sophisticated engine technology in particular require regular expertise and high-quality spare parts to ensure long-term satisfactory use.