Table of Contents

BMW F20 TN43 Engine Reliability Problems and Common Failures

The BMW F20 with its TN43 engine has earned a reputation amongst mechanics and owners for recurring reliability issues that can prove costly if left unaddressed. This compact engine, whilst delivering respectable performance for its size, suffers from several well-documented weaknesses that affect key components including ignition coils, fuel injectors, timing chains, and fuel rail sensors.

Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC  RIDEX Turbocharger

Exhaust Turbocharger, electronically controlled, without fastening/mounting material

RIDEX Turbocharger

Exhaust Turbocharger, electronically controlled, without fastening/mounting material

RIDEX Turbocharger

Turbo, VNT / VTG, Electric, without fastening/mounting material

RIDEX Turbocharger

Turbo, VNT / VTG, Electric, without fastening/mounting material

DELPHI Ignition coil

3-pin connector, 12V

DELPHI Ignition coil

3-pin connector, 12V

Understanding these common failure points can help owners anticipate problems and maintain their vehicles more effectively, potentially avoiding expensive repairs and unexpected breakdowns.

Table: Common Failures

|

Component

|

Common Problems

|

|---|---|

| Timing Chain | Slack, rattling, misfires, engine failure |

| Ignition Coils | Overheating, shorts, oil contamination |

| Fuel Injectors | Tip contamination, coding errors, misfires |

| Fuel Rail Sensors | Pressure anomalies, sensor/pump failures |

| Turbocharger | Wear, oil leaks, power loss |

| Oil Leaks | Valve cover, oil filter housing, pan gaskets |

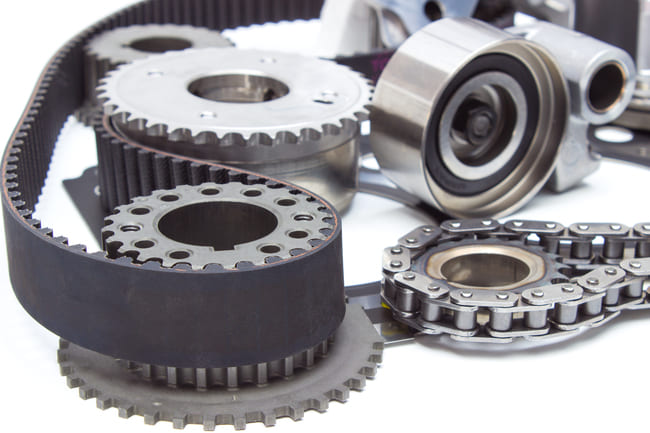

Timing Chain Failures and Related Components

Timing chain premature wear represents one of the most serious reliability concerns with the TN43 engine. The timing chain system experiences accelerated wear due to design limitations and manufacturing tolerances, leading to chain slack that produces characteristic rattling noises during engine startup.

Early symptoms include metallic rattling from the engine bay, particularly noticeable when the engine is cold. As the condition worsens, drivers may experience rough idling, reduced power output, and in severe cases, complete timing failure resulting in catastrophic engine damage.

The timing chain tensioner and guides also fail prematurely, compounding the problem. Regular inspection at service intervals becomes crucial, as replacement costs significantly less than rebuilding an engine after timing failure.

Recommended inspection intervals: Every 80,000 to 100,000 kilometres, with replacement typically required between 120,000 and 160,000 kilometres depending on maintenance history and driving conditions.

Ignition Coil Reliability Problems

Ignition coil failures occur frequently across the F20 range, with multiple contributing factors including excessive heat exposure, electrical faults, and moisture infiltration. These failures manifest as engine misfiring, rough running, reduced fuel economy, and poor acceleration response.

Brand selection proves critical when replacing failed coils. Aftermarket analysis reveals that Delphi ignition coils demonstrate shorter service life compared to Bosch alternatives, which offer superior durability and heat resistance. The experts from Autodoc say the recommended replacement interval for ignition coils for a BMW 1 Series F20 is approximately 105,000 to 150,000 kilometres or every 3.0 to 5.0 years.

Oil contamination from leaking valve cover gaskets can accelerate coil degradation, making it essential to address oil leaks promptly. Replacing all ignition coils simultaneously, rather than individually, ensures consistent performance and prevents repeated failures.

Ignition Coil Diagnosis Process

Professional diagnosis involves scanning for misfire codes, visual inspection of coil boots for damage or oil contamination, and resistance testing of individual coils. Coil boot replacement often accompanies coil renewal to prevent future moisture-related failures.

Fuel Injector Contamination and Coding Issues

Fuel injector problems primarily stem from tip contamination and carbon build-up, particularly affecting engines with higher mileage. Contaminated injectors cause engine vibration, rough idling, and uneven fuel delivery that impacts performance and emissions.

The N13 engine family, closely related to the TN43, demonstrates similar injector vulnerabilities. Carbon deposits accumulate on injector tips due to direct injection design characteristics, requiring periodic cleaning or replacement typically around 160,000 kilometres.

Injector coding requirements add complexity to replacement procedures. New injectors must be properly programmed to match engine management system expectations. Using genuine BMW or OEM-equivalent injectors ensures correct flow rates and long-term reliability.

Worn valve stem seals contribute to oil consumption that can contaminate injectors, creating a cascade effect where multiple systems require attention simultaneously.

Fuel Rail Sensor and Pressure System Faults

Fuel rail pressure anomalies present challenging diagnostic scenarios for technicians. Some owners report abnormal pressure behaviour, including pressure increases after engine shutdown rather than the expected gradual decrease.

These symptoms often relate to faulty low-pressure fuel pump operation or high-pressure pump degradation. However, pressure issues can persist even after replacing pumps, injectors, and variable valve timing solenoids, suggesting system-wide problems rather than single component failures.

Advanced diagnostic equipment becomes necessary to isolate fuel system faults, as symptoms can mimic other engine management issues. Proper diagnosis prevents unnecessary component replacement and reduces overall repair costs.

Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC  DELPHI Ignition coil

3-pin connector, 12V

DELPHI Ignition coil

3-pin connector, 12V

BOSCH Ignition coil

14V

BOSCH Ignition coil

14V

BOSCH Injector

Direct Injection

BOSCH Injector

Direct Injection

Additional Reliability Concerns

Turbocharger wear affects turbocharged variants, with symptoms including power loss, excessive exhaust smoke, and unusual noise during acceleration. Regular oil changes using manufacturer-specified grades help extend turbocharger life.

Oil leaks from valve cover gaskets, oil filter housing gaskets, and oil pan gaskets create secondary problems by contaminating electrical components including ignition coils and sensors. Addressing oil leaks promptly prevents cascading failures.

Preventive Maintenance Strategies

Regular maintenance schedules help mitigate many TN43 engine problems. Oil changes using high-quality synthetic oil at manufacturer-specified intervals reduce timing chain wear and prevent injector contamination. Timing chain inspection at 80,000-kilometre intervals allows early detection before failure occurs.

Using quality replacement parts, particularly Bosch ignition coils and genuine fuel injectors, provides better long-term reliability than cheaper alternatives. Addressing oil leaks immediately prevents contamination of electrical systems.

Key Takeaways

The BMW F20 TN43 engine requires attentive maintenance to address its inherent reliability weaknesses. Timing chain replacement, quality ignition coil selection, injector maintenance, and prompt attention to oil leaks form the foundation of reliable operation. Understanding these common failure patterns helps owners make informed maintenance decisions and avoid costly emergency repairs.

Regular professional inspection combined with quality parts and proper maintenance procedures can significantly extend engine life and maintain reliable operation throughout the vehicle's service life.