Table of Contents

Car wheel hub assembly: failure symptoms and replacement

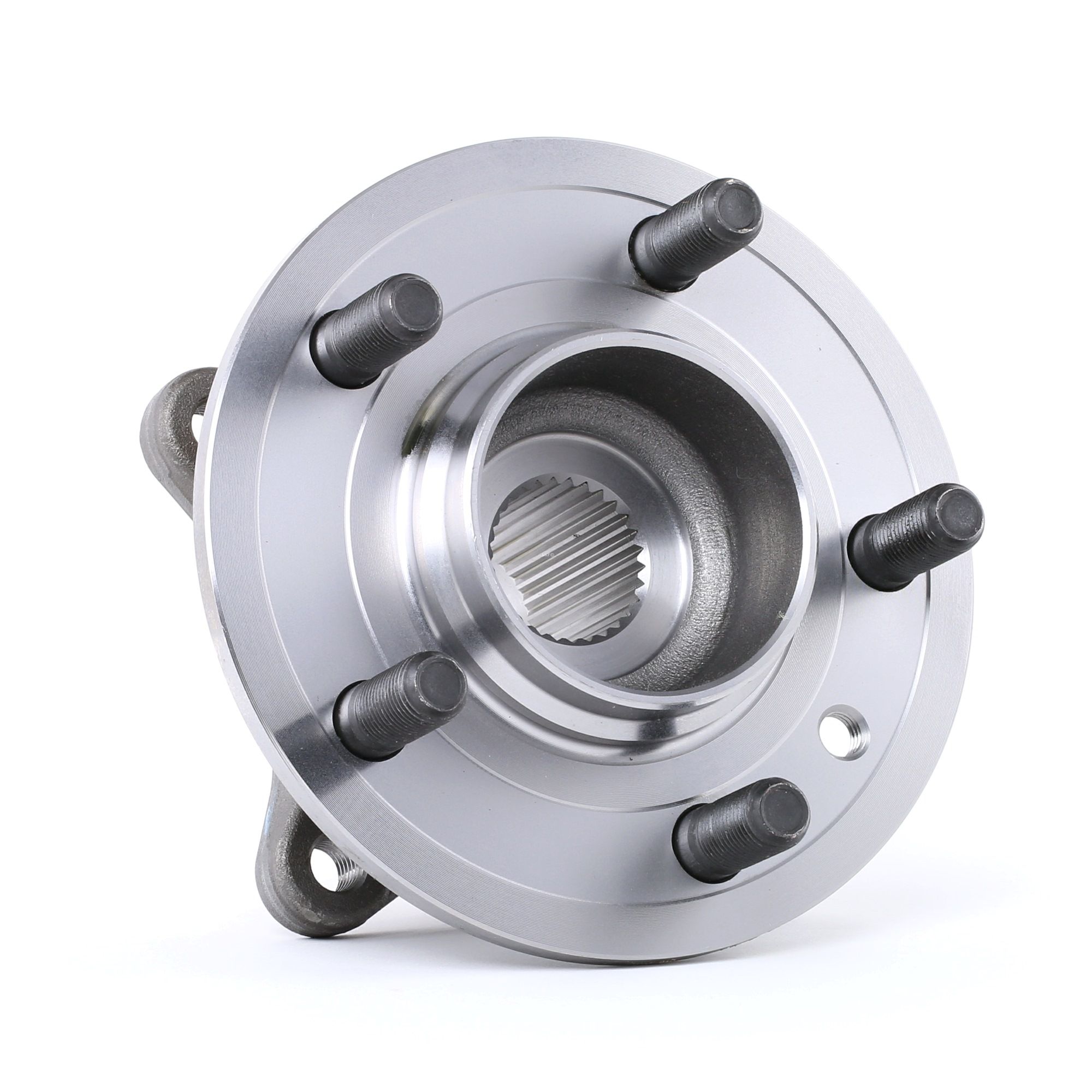

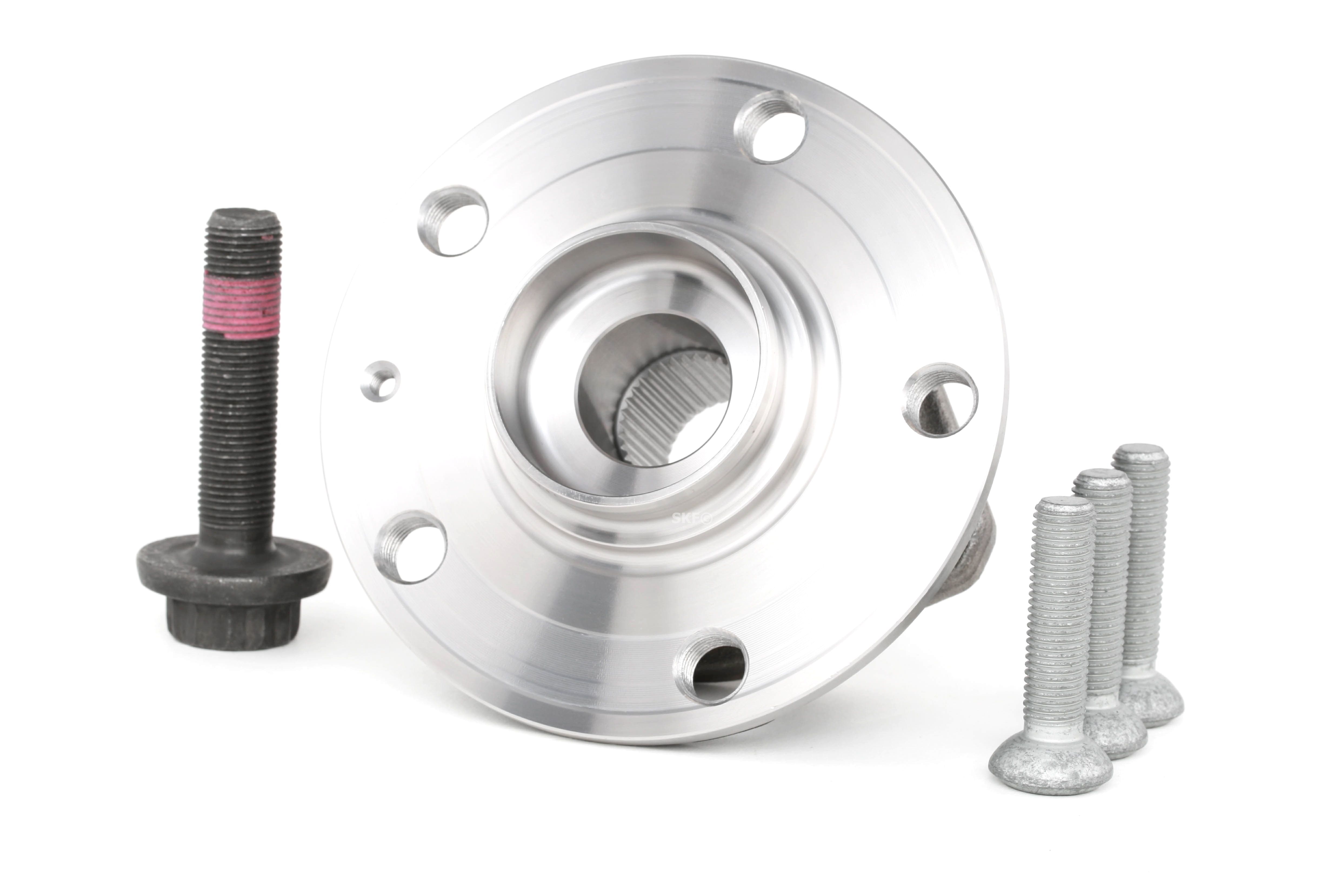

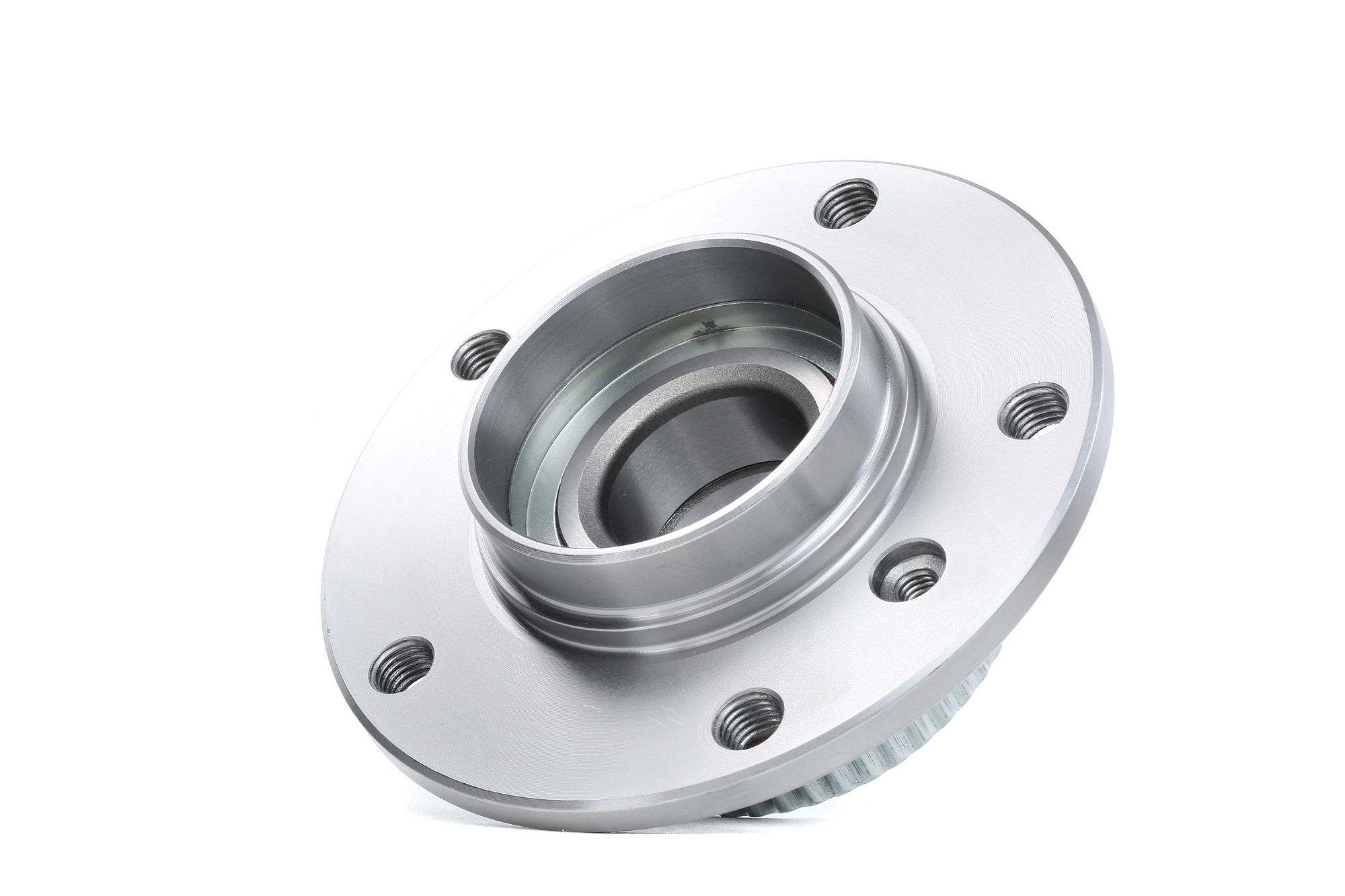

Wheel hubs connect a vehicle’s wheel to the axle and brake system, allowing smooth rotation while supporting the car’s weight. Mounted on the drive shaft, the hub sits between two bearings and transfers forces between the wheel and chassis. Its main function is to provide the rigid wheel journal with a rotating joint.

When does a wheel hub need replacing?

These components are extremely robust and designed to withstand extreme loads. As a result, damage typically only occurs as a result of accidents, severe impacts, or defects. Below, AUTODOC experts explain how to spot a failing hub, when and how to replace it, cost considerations, and pro tips to keep you safe on the road.

Recognising wheel hub failure symptoms

Noise and vibration

- Grinding or humming sounds: as bearings wear, you may hear a low-frequency hum or grinding sound that intensifies with speed.

- Humming when cornering: a worn bearing often changes pitch when turning left or right.

- Clunking: loose wheel bearings or a failing hub nut can produce intermittent clunks during acceleration or braking.

Visible signs

- Uneven tyre wear: a wobbling hub often leads to irregular tread wear on one side of the tyre.

- Grease leaks: dark grease deposits around the wheel edge can indicate a compromised seal.

- Rust and corrosion: surface rust on the hub can be cleaned with a quality car rust remover spray, but deep pitting near the bearing race suggests seal failure, requiring a replacement.

Performance indicators

- Steering pull: a failing hub may cause the steering wheel to drift to one side under normal driving.

- ABS warning light: on modern vehicles, a damaged hub or bearing can trigger the ABS sensor, illuminating the warning light.

What is the service life of a wheel hub?

Wheel hubs are built to last – typically between 84,000 and 100,000 miles under normal conditions. However, front hubs often wear faster than rear ones and may need earlier attention. Replace a hub if you detect the symptoms above, particularly humming or grinding, excessive play, and visible damage, such as cracking.

When replacing the unit, always choose reputable parts. Counterfeits pose a serious safety risk as they may not meet standards and may have defects. A Toyota Corolla owner, for instance, should opt for an original or ECE R90 certified aftermarket Toyota Corolla wheel hub that is designed to match the factory specifications.

Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC  FEBI BILSTEIN Wheel bearing kit

Front Axle Left, Front Axle Right, with fastening/mounting material, Wheel Bearing integrated into wheel hub, with integrated magnetic sensor ring, with ABS sensor ring, 90, 79 mm, Angular Ball Bearing

FEBI BILSTEIN Wheel bearing kit

Front Axle Left, Front Axle Right, with fastening/mounting material, Wheel Bearing integrated into wheel hub, with integrated magnetic sensor ring, with ABS sensor ring, 90, 79 mm, Angular Ball Bearing

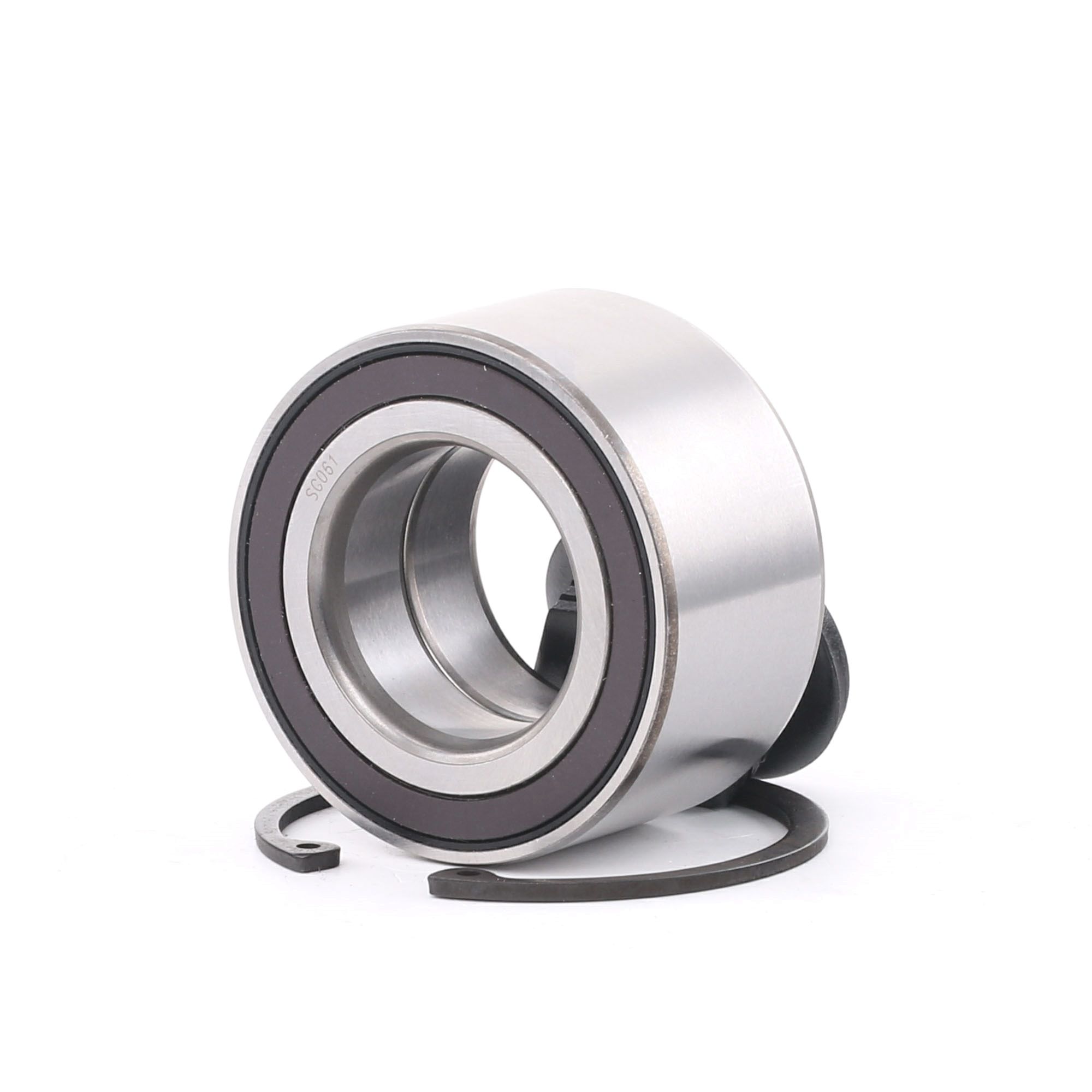

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 136,5, 85 mm

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 136,5, 85 mm

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 149,2, 85 mm

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 149,2, 85 mm

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 208, 87,5 mm

FAG Wheel bearing kit

Photo corresponds to scope of supply, with ABS sensor ring, 208, 87,5 mm

What is the best way to remove a hub?

Old wheel hubs are best removed with the wheel mounted. Once the cap has been removed, the locknut can be loosened with a suitable special wrench. The wheel can then be lifted. It is essential to secure it with an undercarriage block.

If the wheel is removed first, it is important to secure the wheel hub to prevent the propeller shaft from turning. The general DIY steps are listed below. Make sure to check the repair or owner’s manual for your specific model before proceeding.

Tools and safety equipment

Essential tools:

- Jack and sturdy axle stands

- Torque wrench (capable of 20–200 Nm)

- Suitable breaker bar or impact wrench

- Hub puller or slide hammer (if needed)

- Hammer and drift for corrosion removal

- Socket set (including axle nut socket)

Safety first!

Torque specifications

Different makes and models have varying torque requirements for hub nuts and wheel fasteners. Below are some examples (always refer to the vehicle’s service manual for exact figures):

| Make and model | Front hub nut torque |

|---|---|

| VW Golf Mk7 | 100 Nm |

| BMW 3 Series E90 | 110 Nm |

| Ford Focus Mk3 | 85 Nm |

If you need more guidance on securing the hub and wheel, consult our guide:

Step-by-step hub removal & installation

- Lift and secure the vehicle

- Park on level ground and apply the handbrake.

- Place wheel chocks behind the tyres on the other axle.

- Loosen the wheel nuts slightly before jacking (if required).

- Use a jack to lift the vehicle and support it on axle stands rated for the vehicle’s weight.

- Remove the wheel

- Finish removing the wheel nuts and take off the wheel (if required).

- Inspect the brake disc and caliper; secure the caliper out of the way using a bungee cord to avoid strain on the brake hose.

- Access the hub assembly

- Remove any retaining cap covering the axle nut (if applicable).

- Using a suitable socket, loosen the axle nut (often requiring high torque).

- Detach the speed sensor cable if equipped with ABS.

- Unbolt the brake caliper bracket and support the brake assembly.

- Detach the hub from the knuckle

- Unbolt the hub assembly from the steering knuckle (usually 3–4 bolts located behind the hub).

- If the hub is seized, use a hub puller or a slide hammer to separate it.

- Carefully tap around the hub centre with a hammer to break corrosion if necessary.

- Clean and prep

- Inspect the knuckle mounting surface. Remove rust and debris with a wire brush until smooth.

- Check the axle shaft for scoring or damage; clean before reassembly.

- Install the new hub

- Position the new hub assembly onto the axle and align it with the knuckle.

- Hand-thread the knuckle bolts, then torque them evenly to the manufacturer’s specification (e.g., 90–110 Nm).

- Slide the hub fully onto the axle splines, ensuring it sits flush.

- Reassemble brake components

- Refit the brake caliper bracket and torque bolts according to the service manual (typically 30–50 Nm).

- Reconnect the speed sensor if present.

- Torque the axle nut to the specified value (e.g., 100 Nm) in one or two stages, using a torque wrench.

- Replace the axle nut cap if applicable.

- Refit the wheel (if removed)

- Mount the wheel and hand-thread the wheel nuts.

- Lower the vehicle carefully and remove axle stands.

- Use a torque wrench to tighten wheel nuts to the correct torque (e.g., 120 Nm), following a star pattern.

- Final checks

- Spin the wheel by hand to ensure smooth rotation without binding.

- Take the car for a slow test drive, listening for any unusual sounds and checking for vibration.

- Re-check torque on wheel nuts after 50–100 miles of driving.

Cost considerations

- Part prices: entry-level hubs begin at around £13 when purchased as part of a wheel bearing kit. Premium or OEM parts (e.g., those for luxury or performance models) may cost £50–£150 or more. For current online rates, see our wheel hub price page.

- Professional replacement cost: you can expect to spend around £170–£300 per hub assembly, including parts and professional labour for a mid-range vehicle. Performing the job yourself can save on labour costs but requires the right tools and skill.

Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC Sold by AUTODOC

SKF Wheel bearing kit

with integrated ABS sensor, 80 mm

SKF Wheel bearing kit

with integrated ABS sensor, 80 mm

A.B.S. Wheel bearing kit

with integrated magnetic sensor ring, 72 mm

A.B.S. Wheel bearing kit

with integrated magnetic sensor ring, 72 mm

SKF Wheel bearing kit

with flange, with integrated ABS sensor

SKF Wheel bearing kit

with flange, with integrated ABS sensor

FEBI BILSTEIN Wheel bearing kit

Front Axle Left, Front Axle Right, Wheel Bearing integrated into wheel hub, with ABS sensor ring, 143 mm, Angular Ball Bearing

FEBI BILSTEIN Wheel bearing kit

Front Axle Left, Front Axle Right, Wheel Bearing integrated into wheel hub, with ABS sensor ring, 143 mm, Angular Ball Bearing

Preventive maintenance tips

- Regular inspection: during every tyre rotation (roughly every 10,000 miles), ask your mechanic to check for wheel play and unusual bearing noise.

- Monitor driving conditions: rough roads, potholes, or kerb impacts can speed up hub wear, so drive with caution and avoid potholes where possible.

- Keep seals clean: regularly clean brake components to prevent grime buildup, which can compromise hub seals.

- Prompt attention to minor issues: a faint hum or slight vibrations today can become a serious fault tomorrow. Address any unusual sounds immediately.

Frequently Asked Questions (FAQ)

On average, a wheel hub assembly lasts between 84,000 and 100,000 miles, depending on driving conditions and maintenance. Some modern bearings exceed 120,000 miles when properly cared for.

It is not advisable. Even slight noises can indicate a worn bearing that may fail suddenly. Driving on a failing hub risks wheel detachment and loss of control.

OEM hubs ensure a good fit and may come with longer warranties, but quality aftermarket hubs can be equally or even more reliable. To be safe, verify that the aftermarket hub meets or exceeds OEM specifications and check compatibility using the OE part number before making a decision.

Top products related to this topic: