Clutch Master Cylinder: Symptoms, Diagnosis, Replacement & Costs

You press the clutch pedal expecting a smooth gear change, but something feels off. Maybe the pedal sinks too easily, or the gears grind despite your best efforts. The problem might not be the clutch mechanism itself, but a key component that goes unnoticed until it fails: the clutch master cylinder.

This guide will walk you through how the master cylinder works, signs of failure, testing methods, replacement costs, and how to keep it in top condition.

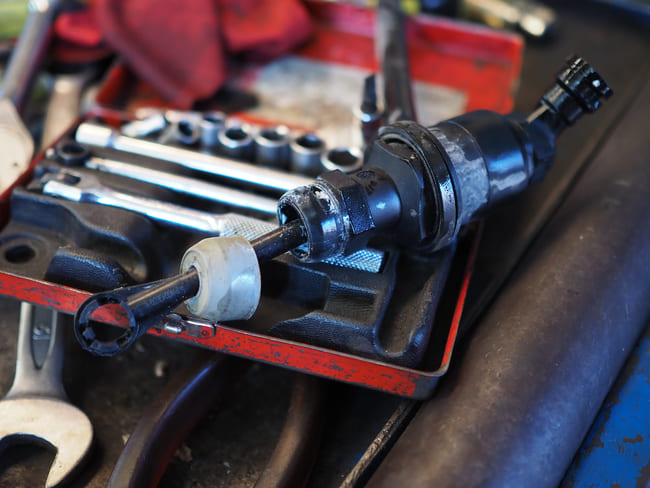

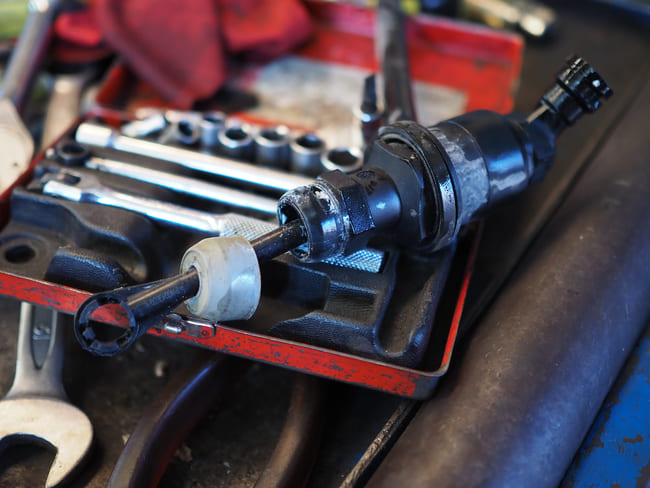

What is a clutch master cylinder?

In a hydraulic clutch system, the master cylinder is responsible for converting the mechanical force from your foot pressing the clutch pedal into hydraulic pressure. This pressure travels through hydraulic lines to the slave cylinder, which disengages the clutch mechanism from the engine and allows you to change gears.

Where is the clutch master cylinder located?

The master cylinder is connected to the clutch pedal in the cabin via a push rod and can typically be accessed from inside the engine bay. You should find it next to the brake master cylinder on the car’s bulkhead.

How does it work?

When you press down the clutch pedal, a push rod activates the master cylinder. The component compresses a hydraulic fluid and sends it through hoses to the slave cylinder. The slave cylinder then moves the clutch fork and release bearing, disengaging the clutch and allowing smooth gear changes. Without proper pressure from the master cylinder, the entire hydraulic clutch system becomes ineffective.

In older vehicles, the clutch tends to be operated using a steel cable rather than fluid, making the system simpler to maintain but not quite as smooth or durable.

Bad clutch master cylinder symptoms

A worn or failing master cylinder can eventually leave your car undriveable. Look out for these early warning signs:

- Spongy or soft clutch pedal – often caused by air in the hydraulic system or internal leaks leading to low fluid.

- Clutch fluid leaks – check around the pedal, firewall, and reservoir. A leak often signals a damaged seal inside the cylinder.

- Difficulty shifting gears – if the system can’t generate enough pressure, the clutch won’t disengage fully.

- Discoloured or low clutch fluid – dark fluid may be contaminated/degraded; low fluid could be a sign of a leak.

- Sticking pedal or inconsistent biting point – could indicate wear, leaks, or a misaligned push rod.

- Unusual noises – squeaking or creaking sounds when the clutch is pressed may point to hydraulic issues.

These symptoms mean it’s time to inspect or replace the components, especially if you drive a model known for clutch or transmission issues.

What causes clutch master cylinder failure?

There are several potential reasons why a master cylinder might fail:

- Worn internal seals – the rubber cup inside the cylinder can degrade over time, causing leaks and pressure loss.

- Contaminated fluid – moisture in the reservoir leads to corrosion and reduced effectiveness.

- Air in the system – poor bleeding during repairs can let air creep in, weakening hydraulic performance.

- Ageing components – as with all moving parts, wear and tear eventually affect the performance of the mechanism.

Can you drive with a bad clutch master cylinder?

Technically, you can but AUTODOC mechanics strongly advise against it. A faulty master cylinder can suddenly lose pressure, making it hard or impossible to change gears. In some cases, it can prevent the clutch from disengaging altogether, potentially causing severe damage to the gearbox or endangering others on the road. Don’t wait until it’s too late.

How to test the clutch master cylinder

Diagnosing issues starts with a basic inspection:

- Check fluid levels – make sure the fluid is between the “min” and “max” marks. Look out for dark or murky fluid.

- Inspect for leaks – examine the firewall, pedal assembly, and hose connections for signs of leaks or corrosion.

- Test pedal feel – press the pedal repeatedly; a spongy or sinking pedal could mean that there is air trapped in the system or a worn cylinder.

- Output line test – disconnect the output line from the master cylinder, block it off, and press the pedal. If the pedal holds firm, the master cylinder is likely functional.

If the cylinder fails these checks, consider a high-quality replacement, such as a Brembo clutch master cylinder, known for reliability and OE-level performance.

Clutch master cylinder replacement cost (UK)

In the UK, the average clutch master cylinder replacement cost is around £200, but this can range from £140 to £450 depending on your vehicle make, model, and local labour rates.

If you’re mechanically inclined, doing the job yourself can save money. However, it’s quite an advanced task that involves bleeding the hydraulic system and removing interior trim, so don’t hesitate to hire a professional if unsure.

Price of parts

Prices vary by brand and car model:

- Budget aftermarket parts: £30–£90

- OE-quality (e.g. Brembo): £30–£130

- Premium/high-performance: £150–£500+

Always compare prices and reviews before purchasing. Premium parts may last longer and include warranties.

How to keep your clutch master cylinder healthy

Prevention is key. Here’s how to extend the life of your clutch master cylinder:

- Check fluid levels regularly – top up with the correct hydraulic fluid and avoid mixing types.

- Avoid aggressive driving – repeated hard shifts or clutch riding strains the system.

- Schedule inspections – during routine maintenance, have your mechanic inspect the hydraulic components.

- Use high-quality parts – when replacing parts, invest in well-known, reliable brands. You can find suitable parts using our vehicle selector or online catalogue, which covers a vast range of makes and models, e.g. Ford Focus clutch master cylinder.

Understanding your clutch system as a whole helps when diagnosing issues. If you're unfamiliar with all the parts involved, explore our guide to clutch system components for a breakdown of how everything works together.

Final words

The clutch master cylinder might be small, but it plays a huge role in safe, smooth driving. Recognising the early signs of failure, knowing how to test it, and understanding your replacement options will keep you in control – literally. Whether you're doing the job yourself or hiring a pro, using quality components will ensure peace of mind on the road.

Top products related to this topic: