What is a crankshaft in a car? Function, structure, and symptoms of malfunctions

The crankshaft is the backbone of the engine, converting the linear motion of the pistons into rotational energy that ultimately powers your wheels. Despite being made from highly durable materials, it can suffer damage due to extreme stress, poor maintenance, or a lack of oil.

Understanding how a crankshaft works, what causes it to fail, and how to spot early warning signs may save you from expensive repairs or a full engine replacement. This guide explores the function and structure of the crankshaft, common symptoms of failure, and the costs involved.

What does a crankshaft do?

In layman's terms, the crankshaft converts the up-and-down movement of the engine pistons into a rotary motion that gets transferred through the transmission to the car wheels. It does this in conjunction with connecting rods and the flywheel.

Due to the rapid, forceful rotational forces and the high temperatures involved, the crankshaft must endure enormous mechanical stress. It also handles vibrations and must remain perfectly balanced to ensure smooth operation and protect surrounding components.

Structure and materials

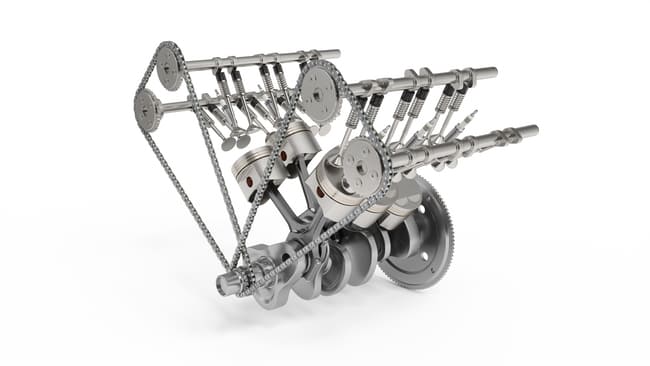

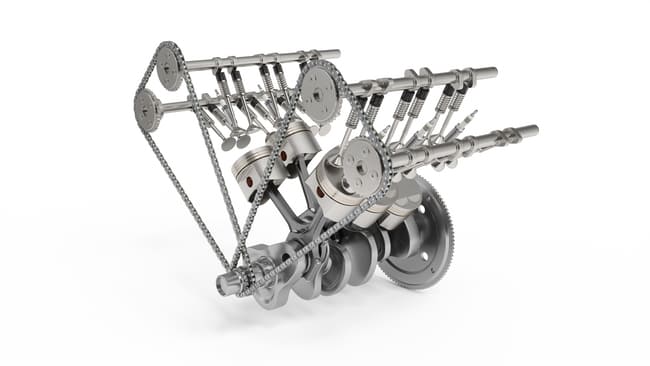

A modern engine crankshaft has an intricate but robust design. It typically consists of the following components:

- Main journals – support the crankshaft inside the engine block.

- Crankpins – connect to the connecting rods.

- Crank webs – link the main journals and crankpins.

- Counterweights – ensure dynamic balance.

- Flywheel connection – stores rotational energy and smooths out engine pulses.

Most crankshafts are made from alloyed steel or using high-strength casting methods, with specific areas (like the journals) hardened to withstand wear. Nitrided or tempered steel is commonly used for its high strength and heat resistance.

The structure will depend on the engine’s specific layout, stroke length, firing order, and number of cylinders. For example, V6 and V8 engines often feature cross-plane or flat-plane crankshafts depending on performance goals.

Role of the crankshaft sensor

To ensure precision timing, the crankshaft’s movement is tracked by a crankshaft sensor. This electronic component monitors rotational position and speed, sending real-time data to the engine control unit (ECU). The ECU then synchronises the fuel injection process and ignition timing for optimal engine performance.

If the sensor fails or sends false signals, it can lead to misfires, poor fuel economy, or even prevent the engine from starting altogether.

What causes crankshaft damage?

Although crankshaft failure is rare in modern vehicles, it’s not impossible – never say never! Common causes of crankshaft failure include:

1. Lack of engine oil

This is by far the most common reason for crankshaft damage. When oil levels drop too low, the bearings are no longer properly lubricated, causing increased friction and overheating. Over time, this can lead to severe wear or even complete failure.

2. Oil contamination

Dirty or degraded oil can damage the crankshaft journals and bearings. Debris and metal particles act like abrasives, accelerating wear.

3. Over-revving or mis-shifting

If you accidentally shift into a lower gear at high speed (e.g., accidentally shifting from 5th gear to 4th gear instead of the 6th), the sudden surge in RPM can cause significant damage to the crankshaft and other internal parts if done repeatedly.

4. Manufacturing defects or poor installation

Though rare, imprecise machining or misaligned bearings can lead to uneven mechanical stress and premature engine failure.

Symptoms of a faulty or damaged crankshaft

Get your crankshaft diagnosed early before it causes havoc. Watch out for these warning signs:

1. Unusual engine noises

- Clacking noise: often linked to worn connecting rod bearings.

- Deep rumbling or knocking: could indicate damage to the crankshaft’s main bearings. If you hear this, turn off the engine immediately.

2. Engine vibration

A worn crankshaft or imbalanced counterweights may cause noticeable engine shaking or unusual vibrations while driving or idling. However, this could also be caused by damaged engine mounts.

If the crankshaft or its sensor isn’t functioning correctly, you will likely experience rough idling, misfires, power losses, or starting difficulties.

4. Warning lights

A faulty crankshaft sensor can trigger the check engine light or put your car into limp mode.

A worn or damaged seal can cause oil to leak out, resulting in a lack of lubrication/oil starvation. You may also see metal particles in the oil left by worn metal parts.

Diagnosing crankshaft problems

Most faults can be diagnosed through a process of elimination and a physical inspection. According to AUTODOC experts, this usually involves the following:

- Checking the crankshaft axial play (end float).

- Inspecting the bearing clearances.

- Measuring the journal concentricity.

- Using diagnostic tools to test the crankshaft sensor signal and check the ECU fault codes.

How much does a crankshaft replacement cost in the UK?

The cost of replacing a crankshaft in the UK can vary widely depending on the make and model of your car, local labour charges, and whether you use new, reconditioned, or used parts.

Here’s a rough breakdown:

| Vehicle type |

Crankshaft (part only) |

Labour costs |

Total estimated cost |

| Small car (e.g. Ford Fiesta, VW Polo) |

£250 – £500 |

£500 – £800 |

£750 – £1,300 |

| Mid-range car (e.g. Audi A4, BMW 3 Series) |

£400 – £700 |

£700 – £1,000 |

£1,100 – £1,700 |

| High-performance or luxury car |

£600 – £1,200 |

£1,000+ |

£1,600 – £2,500+ |

Key factors:

- Labour intensity: the crankshaft is buried deep within the engine. Its removal requires disassembling most of the engine, which is why labour is often more expensive than the parts themselves.

- Part availability: OEM crankshafts normally cost more than aftermarket or reconditioned products.

- Engine type: V6, V8, or performance engines are generally more complex and expensive to work on.

Is it worth replacing?

In many cases, particularly for high-mileage cars, it may be more cost-effective to replace the entire engine with a good-quality used or refurbished unit rather than just the crankshaft. Always compare quotes and ask your mechanic for a full cost-benefit analysis before proceeding.

Can crankshaft damage be prevented?

Yes, crankshaft damage is largely preventable with proper maintenance:

- Regularly check and change your engine oil.

- Use the manufacturer-recommended oil type.

- Keep an eye on oil pressure and temperature.

- Avoid over-revving or aggressive downshifting, as well as harsh acceleration.

- Address warning lights or abnormal engine noise immediately.

These simple habits can extend the life of your motor and prevent damage to components like the shafts, bearings, and oil pump.

Summary

Understanding how it works, recognising early signs of trouble, and performing routine maintenance can help you avoid unnecessary crankshaft problems or worse. When maintained properly, the crankshaft and camshaft can last the car’s entire service life. If issues do arise due to bad driving habits, oil issues, or defects, consult a qualified mechanic to determine whether repair or replacement is more practical for your specific case.

Top engine car spares