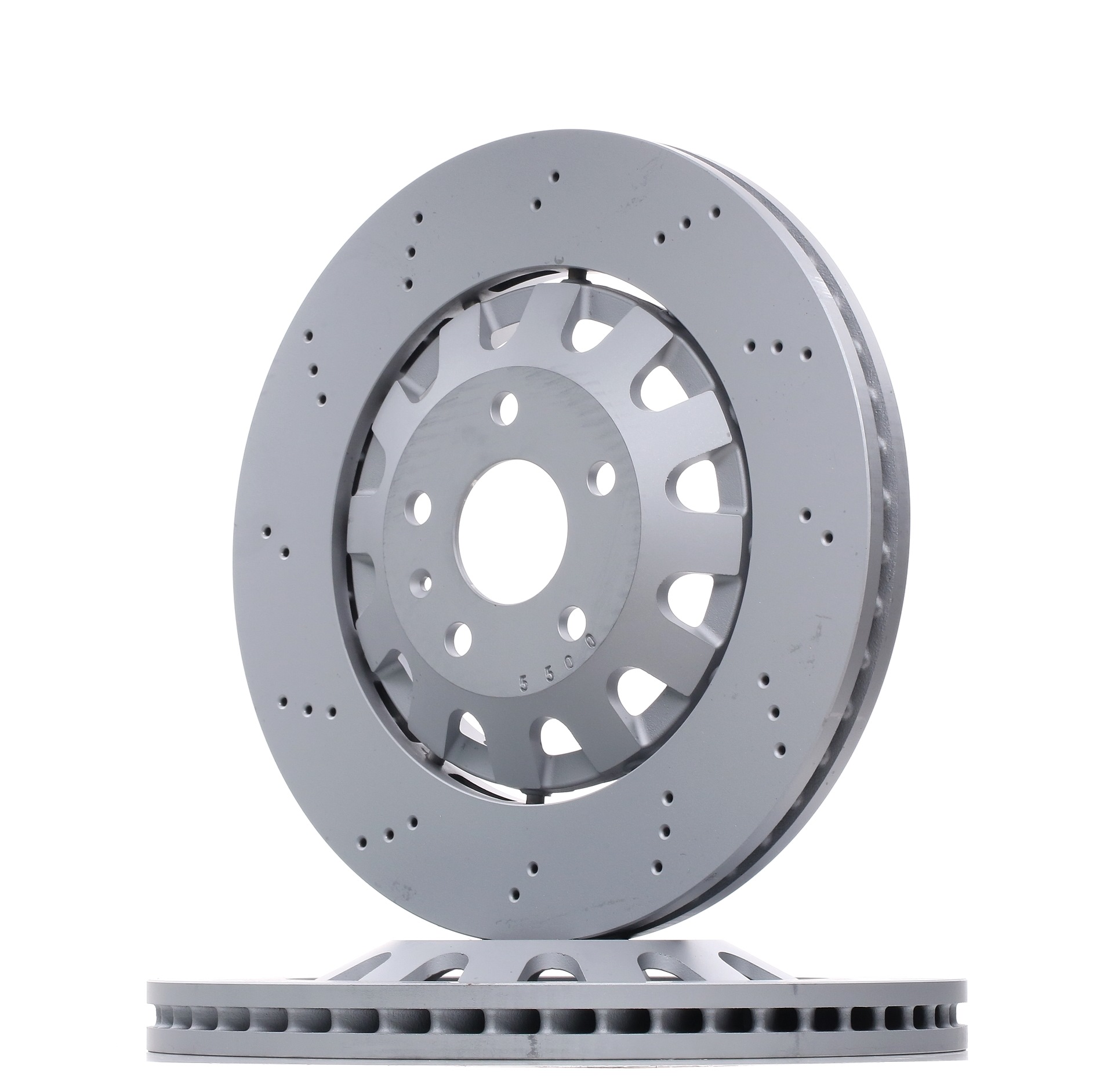

iDisc: 90% less dust when braking

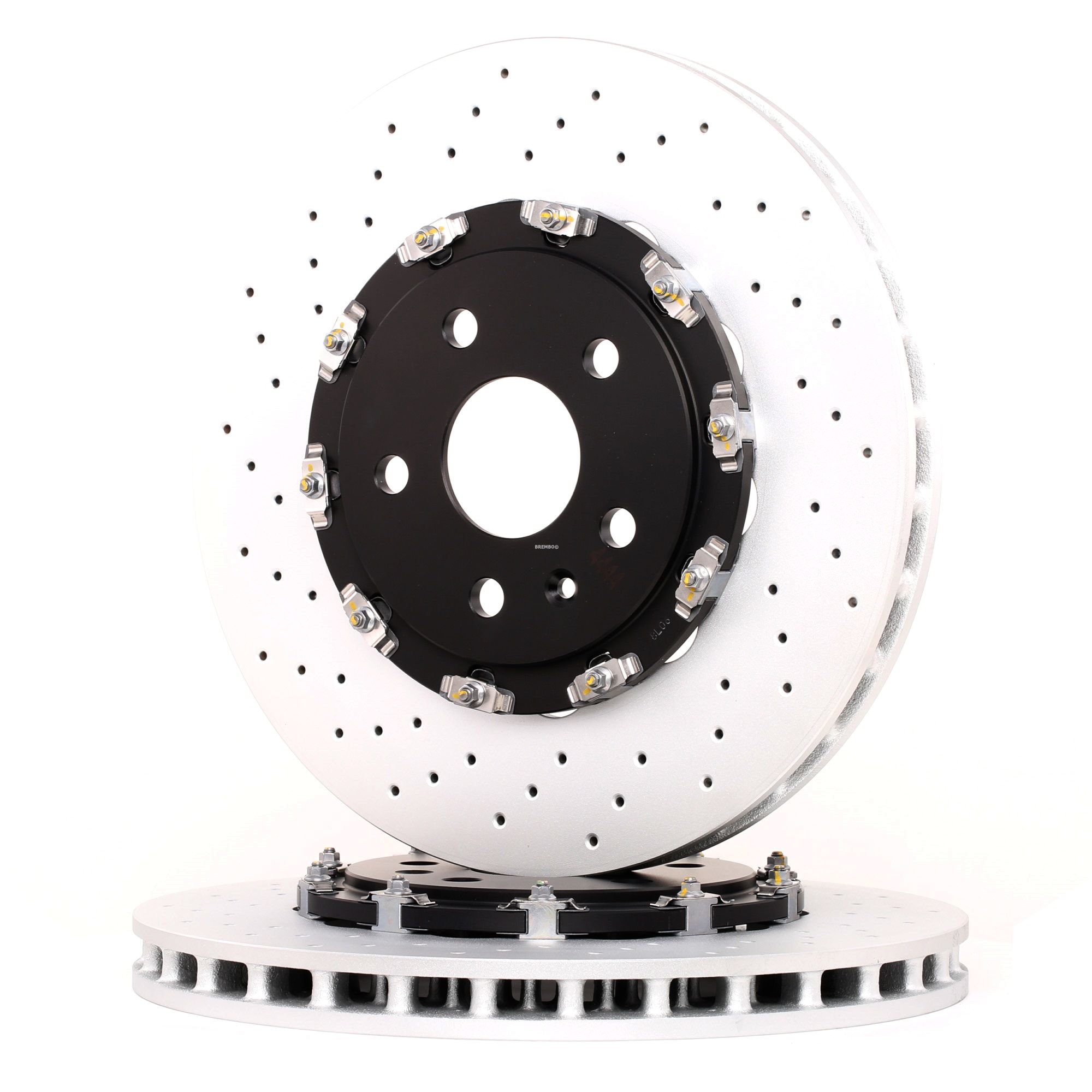

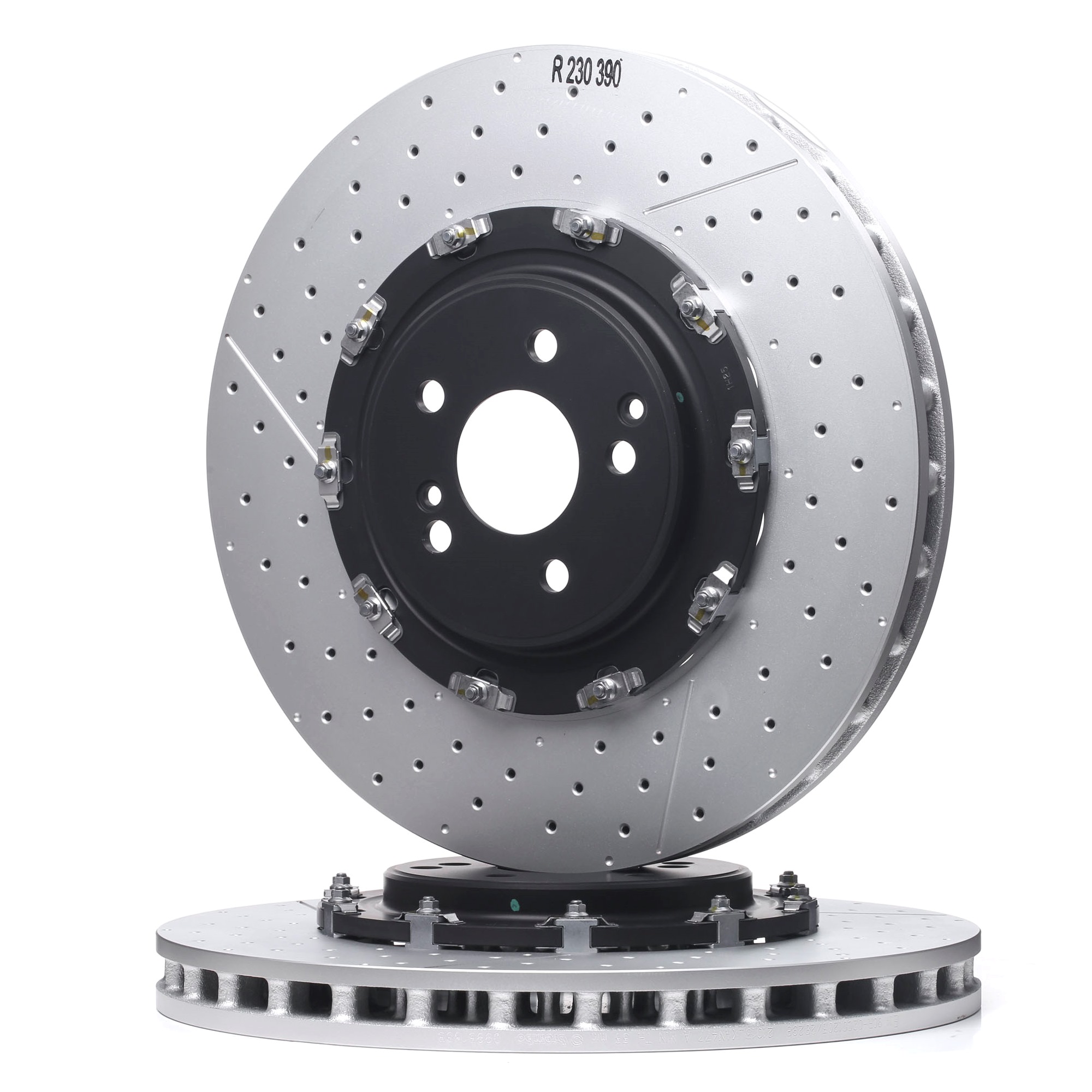

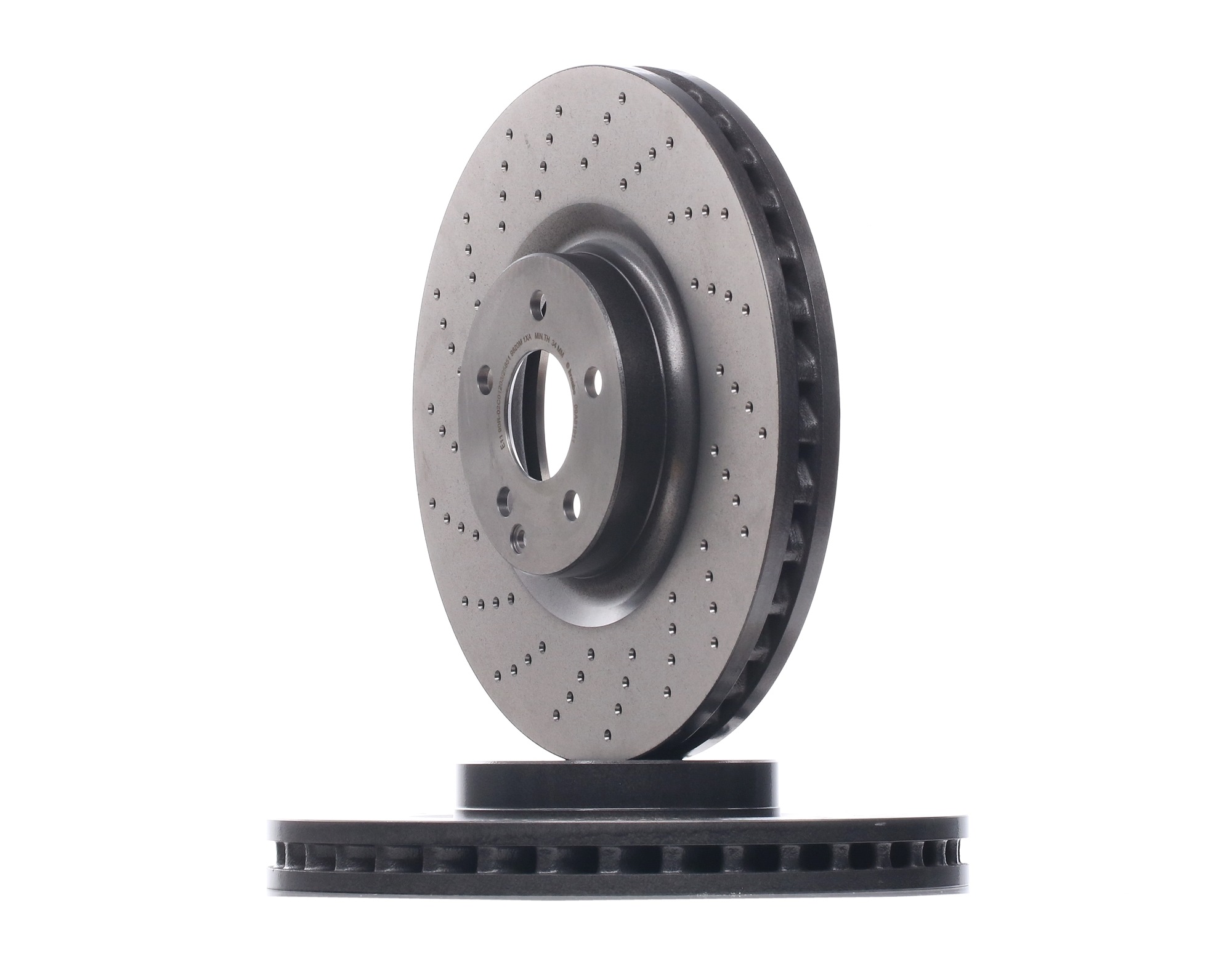

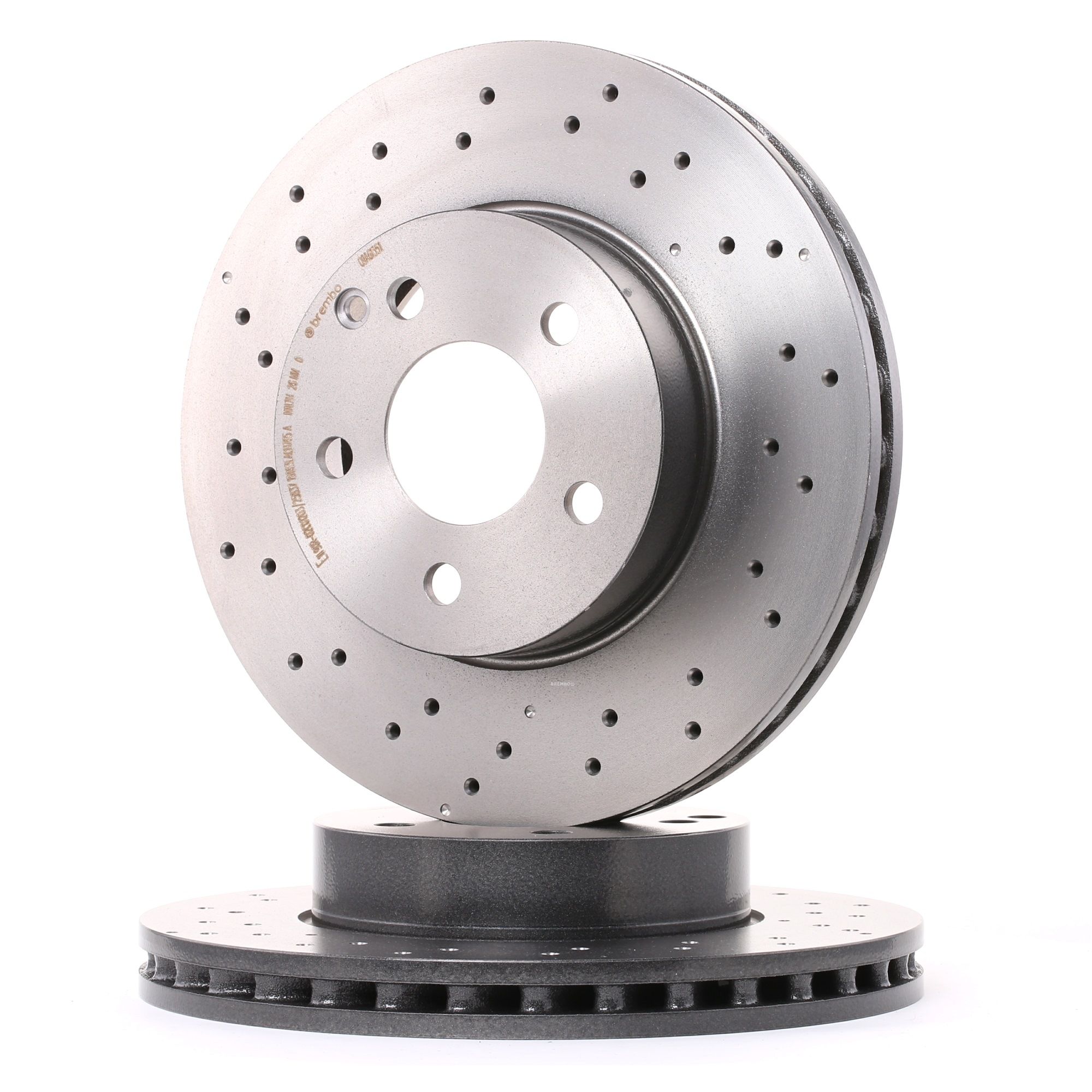

The German company, which is a part of the Robert Bosch GmbH Group, has recently introduced its new development to the world – the brake discs called the iDisc. Their main feature is a fine coat of tungsten carbide due to which they managed to improve the product performance several times.

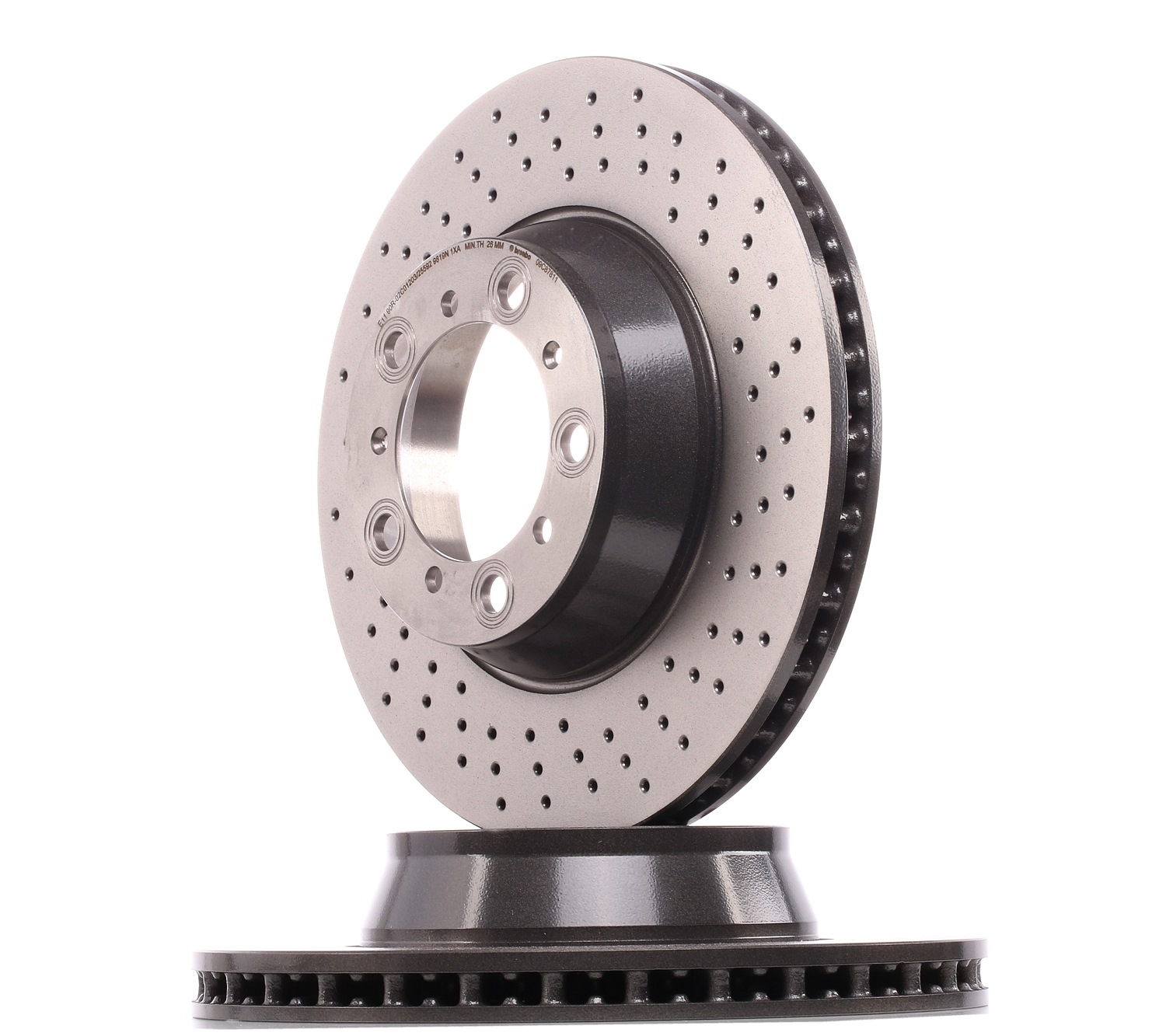

Tungsten carbide is one of the hardest materials in the world, and only a little inferior to diamond. Brake discs with such a coating are resistant to abrasion, and wear twice as slow as cast iron ones. Besides, while braking they produce 90% less dust than usual. Therefore, the iDisc is a significant contribution to the protection of the environment as, according to the statistics, the brake dust makes up nearly 16% of all harmful vehicle emissions.

The reduced abrasion has a practical value as well: having fitted the innovative iDiscs to their cars, drivers can forget about buying special agents to clean dust from wheel rims, saving their time and money.

Another unquestionable advantage of these car parts is their resistance to overheating. Even after several acceleration and deceleration cycles, their performance properties do not worsen. Sport car lovers are sure to appreciate the stylish appearance of the novelty as well. The surface does not grow dim during the entire service life as the manufacturers claim.

Besides, tungsten carbide is corrosion-free, therefore, the effectiveness of braking lasts for a long time. Due to the absence of a film of rust, a secure contact between the disc and the pad is provided immediately as soon as the brakes are applied.

The price of the novelty is three times as high as the price of ordinary cast iron brake discs, and three times as low as the price of ceramic ones. Besides, the technical specifications of the iDisc are similar to the ones of the latter; therefore, it is a good purchase.