Table of Contents

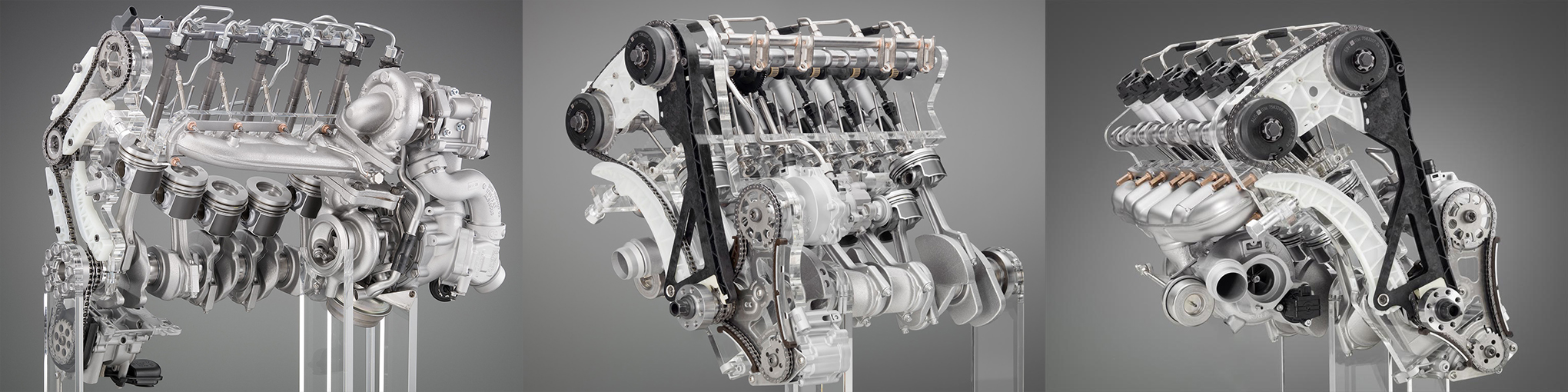

Common rail engines: functions and operating characteristics

Common Rail is a direct fuel injection system installed on vehicles with diesel engines. It has been developed by the Bosch company. Nowadays the common rail system is installed on over 70% diesel engines produced by various manufacturers.

Common Rail system design and operation principle

The basic common rail system components are:

- fuel rail;

- fuel injection pump;

- fuel injectors (piezoelectric actuated or electromagnetic).

Fuel is driven from the tank by the low pressure pump and enters the fuel injection pump where it is compressed by plungers till it reaches the values specified by the control unit. The compressed fuel is fed to the injector rail that acts as a high pressure accumulator and controls fuel supply to each injector. The latter directly inject the fuel into the combustion chamber. Special fuel lines connect the fuel rail outlets and the injectors. The common rail design also includes valves, regulators and sensors that enable the control unit to gather all the required information for executing necessary commands through measurement of various parameters.

Advantages of common rail system engines

- low noise level

- reduced fuel consumption

- low level emission of exhaust gas

Common rail system engines

- MultiJet (Fiat, Alfa Romeo, Lancia)

- VCDi (Chevrolet);

- CDTi (Opel, Vauxhall);

- TDI (Volkswagen, Audi, Skoda, Seat);

- CDI (Mercedes-Benz);

- JTD (Fiat, Alfa Romeo, Lancia)

- DDiS (Suzuki);

- CRD (Chrysler, Jeep);

- TID TTiD (Saab);

- TD4, TDV6, TDV8 (Land Rover);

- dCi (Nissan, Renault);

- XDi (SsangYong);

- D-4D (Toyota);

- CITD (Mazda);

- CRDi (Hyundai, KIA);

- D3, D4 and D5 (Volvo);

- DI-D (Mitsubishi);

- HDi e-HDi, BlueHDi (Citroen, Peugeot);

- i-CTDi (Honda);

- TDCi (Ford).