Car panel adhesive

- Temperature range [°C]: -30°C + 90°C

- Capacity [ml]: 310

- Colour: black

- Item number: 94730

- Our price: £6.99

- Manufacturer: PETEC

- EAN number: 4013558947303

- Temperature range [°C]: -30°C + 90°C

- Capacity [ml]: 310

- Colour: white

- Mounting Time [min]: 15

- Item number: 94530

- Our price: £6.99

- Manufacturer: PETEC

- EAN number: 4013558945309

- Temperature range [°C]: -30°C + 90°C

- Capacity [ml]: 310

- Colour: grey

- Mounting Time [min]: 15

- Item number: 94630

- Our price: £6.99

- Manufacturer: PETEC

- EAN number: 4013558946306

- Packing Type: Cartridge

- Capacity [ml]: 195

- Quantity Unit: Millilitre

- Colour: black

- Pot time [min.]: 60

- Tightening Torque [N / mm²]: 28

- Temperature range from [°C]: -30

- Temperature range to [°C]: +120

- Chemical Properties: hardening, Grindable, Silicon-free, Over-paintable, unbreakable

- Observe technical data

- Observe mounting information

- Item number: 98195

- Our price: £40.99

- Manufacturer: PETEC

- EAN number: 4013558981956

- Condition: New

- Version: PU 6700

- Length [mm]: 257

- Capacity [ml]: 250

- Diameter [mm]: 47

- Packing Type: Cartridge

- Weight [g]: 391

- Item number: 881835

- Our price: £85.99

- Manufacturer: TEROSON

- EAN number: 4002872172560

- Type: one-component

- Capacity [ml]: 400

- Temperature range to [°C]: 80

- Colour: Colourless

- Packing Type: aerosol

- Item number: 94340

- Our price: £12.99

- Manufacturer: PETEC

- EAN number: 4013558943404

- Type: one-component

- Packing Type: Tin

- Capacity [ml]: 400

- Colour: Colourless

- Item number: 6192

- Our price: £16.49

- Manufacturer: LIQUI MOLY

- EAN number: 4100420061929

- Condition: New

- Version: VR 5000

- Type: one-component

- Colour: beige

- Packing Type: aerosol

- Capacity [ml]: 400

- Temperature range from [°C]: -30

- Temperature range to [°C]: +80

- Weight [g]: 500

- Mounting Time [min]: 10

- Item number: 860240

- Our price: £33.49

- Manufacturer: TEROSON

- EAN number: 4002872157871

- Condition: New

- Type: one-component

- Capacity [ml]: 500

- Packing Type: aerosol

- Temperature range from [°C]: -30

- Temperature range to [°C]: +80

- Mounting Time [min]: 2-4

- Colour: Colourless

- Item number: 08080

- Our price: £37.99

- Manufacturer: 3M

- EAN number: 5900422090151

- Capacity [ml]: 25

- Packing Type: Tube

- Item number: 20-B68

- Our price: £1.59

- Manufacturer: MA PROFESSIONAL

- EAN number: 20-B68

- Condition: New

- Type: two-component

- Weight [g]: 35

- Material: Epoxy Resin

- Colour: grey

- resistant to: Petrol, Diesel, Oil, Water

- Product line: KIT MOTORYZACYJNY EPOKSYDOWA

- Item number: E-136

- Our price: £2.99

- Manufacturer: TECHNICQLL

- EAN number: TCHE-136

- Condition: New

- Type: two-component

- Capacity [ml]: 10

- Chemical Properties: Heat-resistant, Chemical Resistant

- Colour: grey

- resistant to: Water

- Temperature range [°C]: -30 ° C / + 80 ° C

- Universal: Yes

- not for vehicle configuration line / variant: PP, PE , PTFE

- Product line: KLEJ 5 MINUT EPOKSYDOWY

- Item number: E-362

- Our price: £2.99

- Manufacturer: TECHNICQLL

- EAN number: TCHE-362

- Condition: New

- Type: two-component

- Weight [g]: 20

- Chemical Properties: Chemical Resistant, hardening, Grindable, Metalliferous, Corrosion resistant

- Colour: black

- resistant to: Oil, Petrol, Diesel

- Mounting Time [min]: 24

- Heat-resistant to [°]: 150

- Product line: MEGA BOND

- Item number: B322

- Our price: £3.29

- Manufacturer: K2

- EAN number: B322

- Condition: New

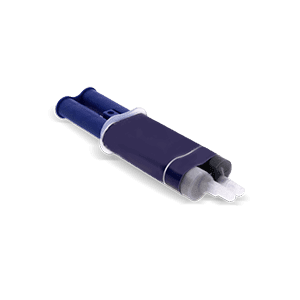

- Type: two-component

- Product line: Epoxy-Metal

- Mixing Ratio: 1:1

- Capacity [ml]: 24

- Packing Type: Blister Pack, Cartridge

- Colour: black / grey

- Mounting Time (in hours): 2-3

- Heat-resistant to [°]: 150

- Item number: 9905

- Our price: £3.29

- Manufacturer: MANNOL

- EAN number: 4036021955551

- Type: two-component

- Product line: Epoxy-Plastic

- Capacity [ml]: 24

- Packing Type: Blister Pack, Cartridge

- Colour: transparent

- Mounting Time (in hours): 2-3

- Heat-resistant to [°]: 150

- Item number: 9904

- Our price: £3.29

- Manufacturer: MANNOL

- EAN number: 4036021955568

- Type: two-component

- Weight [g]: 35

- Quantity Unit: Piece

- Colour: grey

- Universal: Yes

- Product line: UNIVERSAL EPOXY PUTTY

- Item number: E-051

- Our price: £3.29

- Manufacturer: TECHNICQLL

- EAN number: TCHE-051

- Condition: New

- Type: two-component

- Capacity [ml]: 6

- Chemical Properties: Chemical Resistant, Heat-resistant

- Colour: Colourless

- resistant to: Water

- Temperature range [°C]: -30 ° C / + 80 ° C

- Universal: Yes

- Product line: KLEJ BEZBARWNY EPOKSYDOWY

- Item number: E-475

- Our price: £3.29

- Manufacturer: TECHNICQLL

- EAN number: TCHE-475

- Condition: New

- Packing Type: Blister Pack

- Material: Fiberglass

- Colour: transparent

- Length [cm]: 62

- Width [cm]: 22

- Product line: MATA SZKLANA

- Item number: T-055

- Our price: £3.59

- Manufacturer: TECHNICQLL

- EAN number: TCHT-055

- Condition: New

- Type: two-component

- Weight [g]: 40

- Chemical Properties: Chemical Resistant, hardening, Grindable, Metalliferous, Corrosion resistant

- Colour: black

- resistant to: Oil, Petrol, Diesel

- Mounting Time [min]: 24

- Heat-resistant to [°]: 150

- Product line: MEGA BOND

- Item number: B323

- Our price: £3.99

- Manufacturer: K2

- EAN number: B323

- Condition: New

- Type: two-component

- Contents [g]: 28

- Chemical Properties: Plastic, hardening, Chemical Resistant

- Colour: white

- resistant to: Petrol, Diesel, Oil

- Heat-resistant to [°]: 121

- Product line: MEGA TANK

- Item number: B167

- Our price: £3.99

- Manufacturer: K2

- EAN number: B167

- Condition: New

- 1

- 2

- 3

- 4

- 5

Panel adhesive: everything you need to know about car care in our blog

Panel bonding adhesive is a special chemical compound, characterized by high resistance to temperature variations and effects of moisture. It serves for fastening wheel arch extenders and various decorative elements, for attaching trimming elements on certain parts of the car body. It is often used in repair works. It seals the joints, protecting them from corrosion.

What are the types of panel bonding adhesives

According to a product type there are:

- Single component. They are ready to use compounds. Depending on the type and action principle, they may cure under contact with the surface in the absence of oxygen, after solvent evaporation, or when exposed to moisture in the air

- Double component. The active substance and activator, which starts the polymerization process are supplied in separate containers. These compounds should be mixed right before application or applied separately

The following can be used as the main active substance:

- Epoxy resins. Such products are usually double-component. They are notable for excellent adhesion but have low elasticity. They are perfect for drilled holes eliminating, bonding of highly loaded components. Hardening time of the epoxy gluing compounds varies from a few minutes to hours and can depend on the environmental temperature

- Acryl. The products which contain acryl usually belong to double-component mixtures. They are used for fastening plastic, wooden or rubber elements. A few minutes are needed for their shallow curing, up to 24 hours – for total. This group also includes anaerobic sealants, which harden in 15-30 minutes at the temperature of 15–35 °С. They allow to reliably fasten solid constructions, and also eliminate cracks with 0.05-0.6 mm width

- Polyurethane. Compounds based on it are usually single-component. They provide durable, water-resistant and elastic bonding. They serve for sealing welding seams. They are used during mounting of doors, fenders, bonnet reinforcements, spoilers and mouldings. They are characterized by continuous polymerization: up to 2 days

Features of panel bonding adhesives use

- Carefully read the instruction on the pack or the product card. There are adhesives for panel bonding of heat and cold curing. The first ones require heating for activation; the second harden at room temperature.

- Treat the surface before bonding. Remove dirt, moisture and oil from it using special compounds made for bodyworks.

- Apply a special cream to the hands. It will protect the skin from the aggressive influence of chemical components. There are also special products for cleaning hands after work performing

AUTODOC: convenient online-purchases

You will find a wide selection of car chemical products for various purposes at our online-shop. Many customers already appreciated our high-quality service. You can become one of them.

You are saving time and money making purchases at our shop. The convenient search system will help you to find a needed product without problems. High speed of orders processing and automated warehouses promote fast delivery. Frequent promotions and significant discounts allow to buy panel bonding adhesives at the lowest price.